The Inventory Challenge You Can’t Ignore

In today’s fast-paced business environment, inventory can make or break a company. Customers expect fast delivery, zero stockouts, and consistent availability while leadership demands leaner operations and lower carrying costs. Unfortunately, unpredictable demand patterns, supplier delays, and global disruptions create a chaotic balancing act.

Even the most experienced planners struggle with questions like:

- How much inventory should we carry to meet demand without overstocking?

- Which SKUs are at risk of running out?

- How can we respond to supplier delays without costly emergency measures?

A single miscalculation can result in thousands or even millions in lost revenue. Manual tracking, disconnected systems, and outdated forecasting tools can’t keep up with the speed and complexity of modern supply chains.

This is where AI Inventory Optimization steps in, turning chaotic guesswork into intelligent, data-driven decisions.

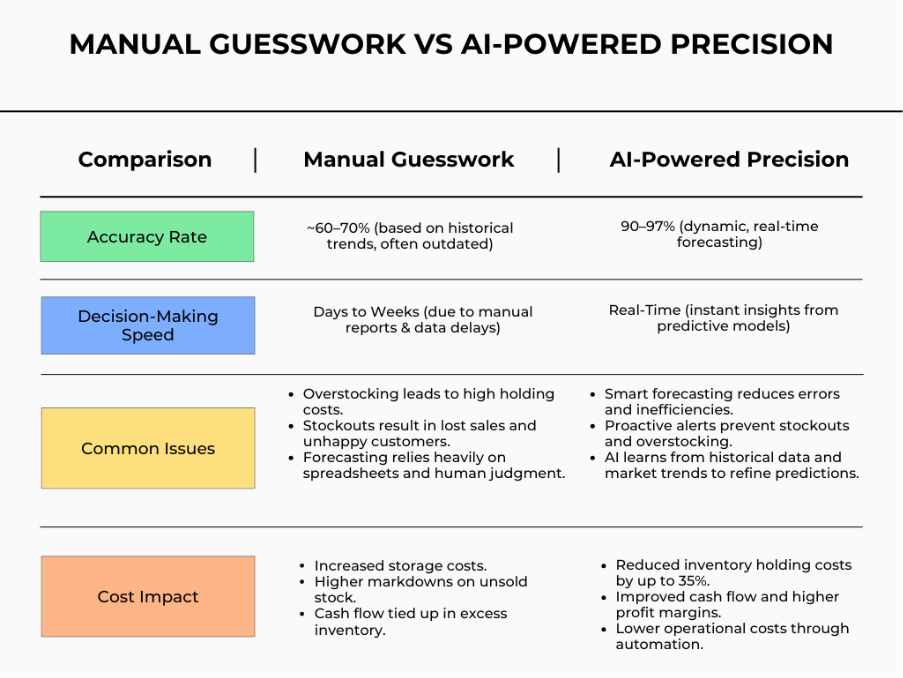

Why Traditional Inventory Management Falls Short

Overstocking and Stockouts: The Expensive Balancing Act

Traditional inventory management methods rely heavily on historical data and static rules, reorder points, safety stock levels, and manual adjustments. While this approach worked in the past, it is no match for today’s rapidly shifting demand patterns and global supply chain complexities.

Key problems with traditional methods include:

- Overstocking – Leads to excess carrying costs, wasted warehouse space, and inventory obsolescence.

- Stockouts – Result in lost sales, poor customer satisfaction, and damaged brand reputation.

- Forecasting Errors – Manual methods or simple spreadsheets can’t account for seasonality, sudden demand spikes, or supplier disruptions.

Why Guesswork is Risky

Spreadsheets may help track inventory, but they don’t provide predictive insights. Worse, they can’t automatically adjust forecasts as new data comes in-resulting in delayed reactions and missed opportunities.

AI changes this by learning from multiple data sources historical patterns, real-time sales, market conditions, and even external signals to deliver proactive insights instead of reactive reports.

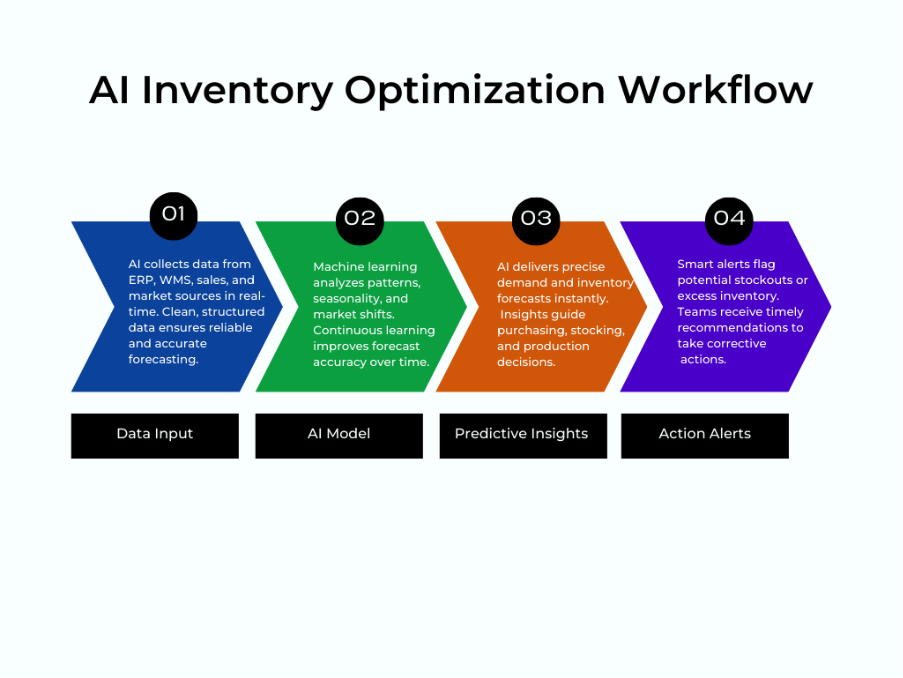

How AI Inventory Optimization Actually Works

AI Inventory Optimization uses advanced algorithms and machine learning models to transform raw data into accurate forecasts and actionable insights. Here’s how it works step by step:

Data Aggregation: AI pulls information from multiple sources: ERP systems, warehouse management systems, sales platforms, and even supplier lead-time data.

Predictive Forecasting: Machine learning analyzes historical trends, seasonality, and market signals to predict demand with high accuracy.

Optimization Engine: AI recommends optimal stock levels by SKU, region, and warehouse—balancing demand with carrying costs.

Real-Time Alerts: Smart notifications are triggered when anomalies occur, like unexpected demand spikes or supplier delays.

Continuous Learning: AI models improve over time, incorporating new data to fine-tune forecasts and inventory plans.

This is not guesswork—it’s predictive precision, giving businesses a real-time advantage.

The Big Wins You’ll See with Inventory AI

Organizations adopting AI Inventory Optimization are experiencing measurable gains across operational efficiency, cost savings, and profitability. By combining real-time data processing, predictive analytics, and proactive insights, AI delivers results traditional methods can’t match.

Fewer Stockouts – Seamless Product Availability

Stockouts not only frustrate customers but also lead to lost revenue and damaged brand reputation. AI-powered forecasting analyzes historical sales data, seasonality patterns, promotional impacts, and even external factors like market trends to predict demand with higher accuracy. This ensures shelves stay stocked and customer loyalty grows—while preventing costly last-minute procurement fixes.

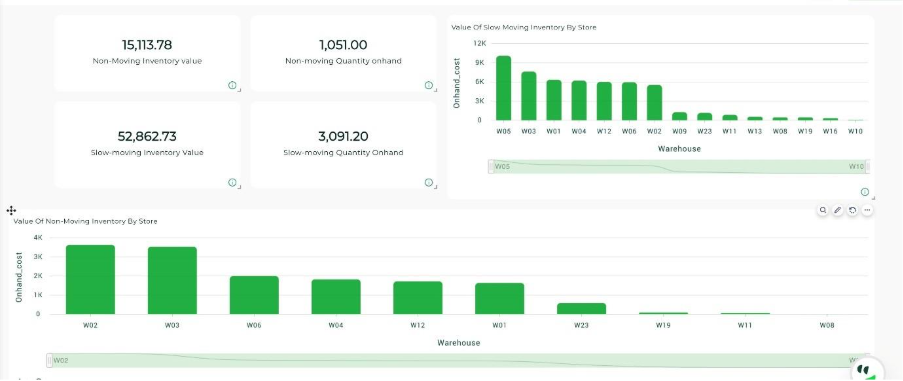

Lower Holding Costs – Optimize Storage and Working Capital

Overstocking is one of the largest drains on working capital and warehouse space. Inventory AI minimizes excess inventory by continuously monitoring sales velocity, lead times, and demand shifts. As a result, businesses can free up capital tied to unsold goods, reduce warehouse costs, and avoid unnecessary markdowns or product obsolescence.

Faster Decision-Making – Real-Time Insight Delivery

Traditional reporting methods often delay critical supply chain decisions due to manual data gathering and processing. AI provides real-time dashboards and predictive alerts, giving leaders the confidence to act swiftly—whether it’s adjusting production schedules, renegotiating purchase orders, or responding to sudden market changes. The speed of decision-making becomes a competitive advantage.

Improved Profit Margins – Precision-Driven Profitability

Aligning inventory levels with actual demand reduces waste, avoids costly rush orders, and ensures the right products are available in the right place at the right time. This directly impacts profitability by minimizing markdowns and stockouts while optimizing sales opportunities. AI makes it possible to strike the perfect balance between inventory availability and cost efficiency—ultimately boosting overall margins.

Smarter Inventory with ConverSight.ai

ConverSight.ai takes AI inventory optimization to the next level with a platform designed for business users—not just data scientists.

Key Advantages of ConverSight.ai

- Conversational AI Interface – Ask simple questions like “What are my top underperforming SKUs this month?” and get instant answers.

- ERP & Supply Chain Integration – Works seamlessly with platforms like NetSuite, Dynamics, Odoo, and SAP.

- Proactive Recommendations – AI not only identifies risks but also suggests corrective actions before issues escalate.

- Scalability & Security – Designed to support growing businesses while keeping data secure.

- Proven Results – Multiple enterprises across retail, manufacturing, and distribution have already seen measurable ROI.

See How It Works → ConverSight.ai Inventory Solution Page

Case Study: AI Inventory Optimization in Action

Case Study: House of Spices – Smarter Forecasting with ConverSight’s Athena

Industry: Food & Beverage Manufacturing & Distribution (Wholesale/Manufacturer of Indian Food Products)

Overview

House of Spices, one of Asia’s largest spice companies, faced enormous challenges with manual forecasting across thousands of SKUs—including highly perishable items. Seasonal demand fluctuations and reliance on outdated data led to frequent forecasting errors, waste, and costly last-minute procurement shifts.

Solution with Athena

ConverSight’s AI-powered assistant, Athena, transformed their operations by providing:

- Multi-model Forecasting: Three forecast perspectives—sales projections, AI-generated, and actual sales—allowing refined alignment with real demand.

- Seasonality-Aware Inventory Management: Athena accounts for demand spikes, price shifts, and purchasing patterns to maintain optimal stock levels and reduce spoilage.

- Real-Time Adjustments: Procurement teams receive reliable, dynamic forecasts, reducing last-minute corrections.

- Sales Performance Enhancement: Forecast accuracy empowers sales teams to set realistic targets and boost revenue effectiveness.

Business Impact

- 30% improvement in forecasting accuracy

- 20% reduction in inventory waste

- 50% fewer computational resources required

Ruby Gangwar, Senior Planning Manager at House of Spices, shared:

Athena has significantly improved our demand forecasting accuracy. We previously struggled with predicting seasonal spikes, but Athena’s advanced modeling and adaptive learning have helped us refine our approach. By continuously analyzing SKU-level data, we can now make better decisions and optimize our supply chain planning. The ability to freeze forecasts for key periods and validate predictions with actual sales data has given us greater confidence in our planning. The improvements we’ve seen in forecast accuracy are game-changing for our operations.

Key Highlights

| Area | Transformation with Athena |

| Forecast Accuracy | Incremental alignment with real demand improves planning |

| Inventory Reduction | Less waste from expired products and better stock control |

| Operational Efficiency | Real-time adjustments and fewer manual interventions |

| Sales Enablement | Smarter target setting and predictable performance |

Explore More Customer Success Stories → Case Studies Page

Getting Started with AI Inventory Optimization

The good news? Implementing AI doesn’t have to be a lengthy or complex process. Modern AI platforms are designed for quick deployment, minimal IT overhead, and immediate value creation. Here’s a practical roadmap to guide your transition toward smarter inventory management:

Audit Current Inventory Practices

Begin by evaluating your existing inventory management processes. Look for:

- Areas of inefficiency, such as recurring stockouts or excessive overstocking.

- SKUs with inconsistent demand patterns or low turnover rates.

- Missed revenue opportunities caused by outdated forecasting methods.

This audit provides a baseline for measuring improvement and helps prioritize where AI can deliver the greatest impact.

Integrate with Existing Systems

AI works best when it can access accurate, real-time data. Integrating with core systems—ERP (Enterprise Resource Planning), WMS (Warehouse Management System), and procurement platforms—ensures seamless data flow. With ConverSight.ai, this integration is designed to be smooth, avoiding the need for large-scale infrastructure changes or heavy IT involvement.

Run a Pilot Program

Instead of launching AI across your entire supply chain at once, start small. Identify high-impact SKUs or critical product categories where demand volatility or inventory inefficiencies are most costly. Running a pilot allows you to:

- Validate the accuracy of AI-driven forecasts.

- Measure improvements in inventory turnover, service levels, and cost savings.

- Build internal confidence in AI’s ability to drive results.

Scale Across Operations

Once the pilot proves successful, expand AI inventory optimization across all locations, product lines, or regions. At this stage, businesses often begin to see exponential benefits—not only in forecasting but also in procurement, production planning, and cash flow management.

Why ConverSight.ai?

ConverSight.ai’s QuickStart approach means you can begin seeing measurable results in weeks, not months. With pre-built dashboards, predictive models, and seamless system integration, businesses accelerate time-to-value while reducing implementation risks.

Conclusion: Why AI Inventory Optimization is a Competitive Advantage

Your ERP is excellent at storing data. But making fast, smart, and profitable decisions requires AI-driven insights.

AI Inventory Optimization ensures that:

- Inventory is aligned with real demand.

- Stockouts and overstocking are minimized.

- Decision-makers act proactively, not reactively.

Businesses that adopt AI now are gaining a significant competitive edge—reducing costs, improving service levels, and boosting profitability.

Ready to make your ERP smarter?

Take a demo and see how ConverSight.ai can transform your inventory management. Book a demo and claim your $100 offer → https://promotion.ConverSight.ai/quick-start-ai-erp-demo