How manufacturers are using AI to make production smarter, faster, and more sustainable.

A Smarter Way to Manufacture

Manufacturing has always been about efficiency, precision, and innovation. But in today’s environment—where supply chains are unpredictable, margins are shrinking, and customers expect faster delivery—traditional methods are no longer enough.

Artificial Intelligence (AI) is transforming how products are made, monitored, and managed. It goes beyond automation to enable smarter decision-making, predictive insights, and end-to-end visibility. From forecasting demand to preventing downtime, AI helps manufacturers move from reactive problem-solving to proactive optimization.

Manufacturers who adopt AI aren’t just keeping up—they’re getting ahead.

Why Manufacturers Are Turning to AI

The manufacturing sector is under pressure like never before. Rising costs, labor shortages, and global supply chain disruptions have forced manufacturers to rethink their operations. At the same time, there’s a growing emphasis on sustainability, transparency, and customer satisfaction.

Here’s why AI adoption is accelerating across the industry—and why understanding the benefits of AI in manufacturing is crucial:

- Cost control and productivity: AI identifies inefficiencies and optimizes production, helping reduce waste and improve throughput.

- Supply chain volatility: AI-powered analytics enable quicker, more informed decisions amid changing market conditions.

- Sustainability demands: Energy and material efficiency are no longer optional; AI helps track and improve both.

- Proactive operations: Instead of reacting to issues, AI allows manufacturers to anticipate and prevent them.

With the right AI infrastructure, manufacturers can achieve stability, resilience, and innovation—all at once.

Discover how ConverSight helps manufacturers use AI for better decision-making. Learn More!

Benefit 1: Improved Equipment Reliability with Predictive Maintenance

Unexpected equipment failure is one of the biggest productivity killers in manufacturing. AI-powered predictive maintenance helps change that story.

By continuously analyzing sensor data, machine usage, and environmental conditions, AI can predict when a machine is likely to fail—long before it happens. Maintenance teams can then schedule repairs or part replacements during planned downtimes, avoiding costly interruptions.

Key benefits:

- Reduce unplanned downtime by anticipating issues early.

- Optimize maintenance schedules and resource allocation.

- Extend equipment lifespan through condition-based maintenance.

Predictive maintenance turns maintenance from a cost center into a strategic advantage.

Benefit 2: Consistent Product Quality

Quality control has always been critical—but it’s getting a powerful upgrade with AI.

AI-driven vision systems can detect microscopic defects or inconsistencies in products that human inspectors might miss. They provide real-time feedback to operators, ensuring immediate corrections. This results in fewer defects, less rework, and reduced material waste.

Beyond inspection, AI improves traceability, helping manufacturers document production processes for compliance, audits, and customer trust.

Outcome: Better quality, less waste, and greater customer satisfaction.

Benefit 3: Smarter Supply Chain and Inventory Planning

Volatile markets and shifting consumer demands have made accurate forecasting more essential than ever. AI helps manufacturers stay ahead with smarter, data-driven supply chain management.

By analyzing real-time sales, supplier performance, and external factors such as weather or geopolitical events, AI enables dynamic inventory and demand forecasting.

AI in the supply chain means:

- Anticipating demand spikes or slowdowns with precision.

- Preventing stockouts and overproduction.

- Optimizing supplier and material management.

- Adapting quickly to disruptions.

These efficiencies highlight another major benefits of AI in manufacturing—turning data into agility and resilience.

Benefit 4: Supporting Sustainability Goals

Manufacturers are under increasing pressure to meet sustainability and ESG (Environmental, Social, and Governance) standards. AI plays a pivotal role in helping them achieve those targets.

From monitoring energy consumption to tracking material usage, AI uncovers inefficiencies and suggests ways to reduce waste. It can even simulate alternative production methods to minimize environmental impact.

AI-driven sustainability benefits:

- Reduced energy and resource usage.

- Optimized recycling and waste management.

- Compliance with sustainability reporting standards.

- Data-backed progress toward ESG goals.

AI enables not just greener factories—but smarter, cleaner, and more efficient ones.

Benefit 5: Helping People Work Smarter

AI isn’t just about machines—it’s about empowering people.

AI assistants can provide real-time insights into operations, answer data questions instantly, and help employees make faster, more confident decisions. From the shop floor to the front office, workers can focus on higher-value tasks instead of repetitive data entry or manual reporting.Additionally, AI improves workplace safety by monitoring conditions and alerting teams to potential risks before incidents occur.

AI enables people and machines to work in harmony—boosting safety, communication, and productivity.

How Manufacturers Are Seeing Results

Across industries, AI and intelligent automation are transforming operations — not in theory, but in measurable outcomes that drive real business value.

- Automotive: Predictive analytics and machine learning models are optimizing production schedules, improving equipment uptime, and reducing defect rates resulting in higher quality and lower rework costs.

- Food & Beverage: AI-powered demand forecasting enables manufacturers to balance production with real-time market demand — helping reduce waste, optimize inventory, and manage shelf life more effectively across distribution channels.

- Chemical: Real-time process optimization and AI-driven monitoring are lowering energy consumption, stabilizing batch quality, and improving product consistency, while supporting sustainability goals.

The common thread? Smarter decisions, faster results, and continuous improvement.

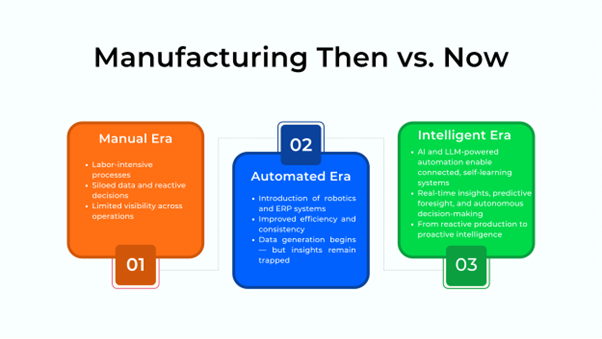

Building the Future of AI in Manufacturing

AI is no longer a distant vision or a privilege reserved for tech giants — it’s becoming a core enabler of transformation for manufacturers across every segment, size, and geography. From small and mid-sized operations to global enterprises, organizations are realizing that AI can reshape how they plan, produce, and perform — not in years, but in weeks.

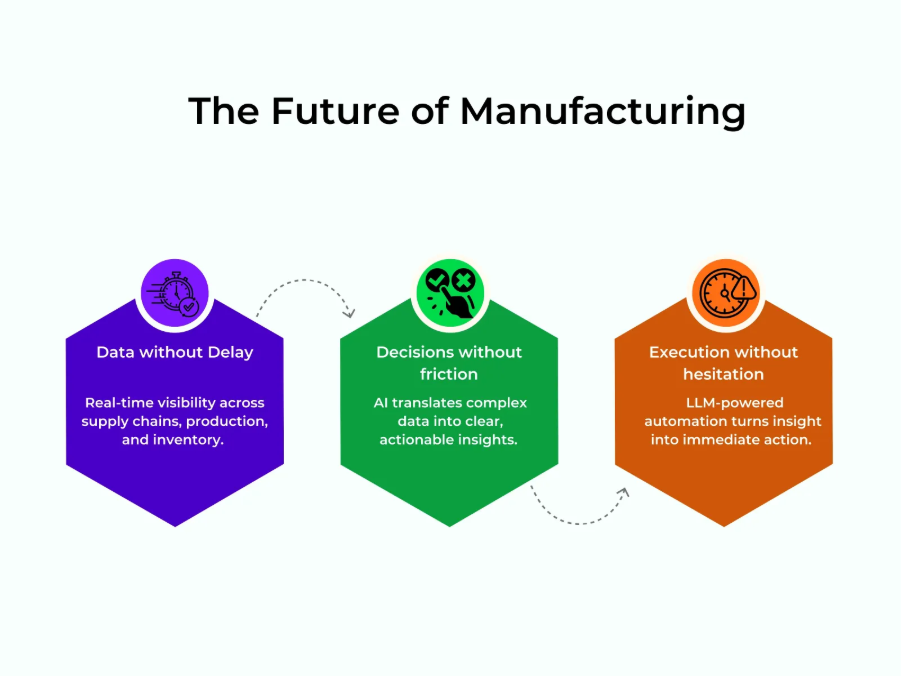

For decades, manufacturers have relied on historical data, spreadsheets, and disconnected systems to make critical decisions. Today, those limitations are being replaced by real-time intelligence and predictive visibility. AI brings context, foresight, and automation together, allowing every stakeholder — from the shop floor to the boardroom — to make smarter, faster, and more confident decisions.

With solutions like ConverSight’s QuickStart AI Solution, manufacturers can begin this journey without complexity or delay. The platform enables instant access to insights through natural, conversational interactions, removing the barriers of data silos and technical dependencies. Within days, teams can start asking questions, uncovering inefficiencies, and identifying opportunities for optimization — all through an intuitive AI assistant.

Beyond efficiency, AI also drives sustainability and resilience. By predicting demand shifts, optimizing energy usage, and improving resource allocation, manufacturers are not only lowering costs but also advancing environmental and operational goals. As supply chains grow more complex, this intelligence becomes the foundation for agility and long-term competitiveness.

Ultimately, AI in manufacturing is about control, clarity, and continuous improvement. It transforms uncertainty into opportunity — enabling businesses to anticipate what’s next, adapt instantly, and operate with confidence in any market condition.

The future belongs to manufacturers who act now. The sooner they embrace AI, the faster they’ll unlock measurable gains in efficiency, productivity, sustainability, and profitability shaping a new era of intelligent, connected manufacturing.

Explore more about QuickStart AI ERP and Supply Chain AI Solutions – ConverSight

Final Thought

AI is redefining manufacturing from the inside out—turning data into actionable insights, empowering people to make smarter and faster decisions, and transforming traditional factories into fully connected, intelligent ecosystems. From predictive maintenance and automated quality control to supply chain optimization and real-time process monitoring, AI is reshaping every part of the production lifecycle.

The question isn’t whether manufacturers should adopt AI, but how quickly they can integrate it to stay competitive in an increasingly dynamic market. Those who embrace AI now will lead the next era of efficiency, innovation, and operational excellence.

Start your AI journey today! Book a demo with ConverSight and explore our Manufacturing Solutions].