How AI Is Transforming Manufacturing, Distribution, and Retail — Faster Than Ever

How Inventory Optimization Software Is Evolving

For small and mid-sized businesses (SMBs), the ability to stay efficient, agile, and customer-focused has never been more important. In today’s volatile markets, customer expectations are rising, supply chains are under pressure, and even minor inefficiencies can cut deep into margins. The businesses that succeed today – whether they manufacture, distribute, sell online, run retail locations, or operate hybrid models – are the ones that adapt quickly with clear data and connected processes. Yet for many SMBs, achieving that level of control can feel out of reach. Manual spreadsheets, legacy systems, and disconnected data often lead to overstocked shelves, fulfillment delays, stockouts, or lost sales opportunities. That’s where inventory optimization software comes in. These tools go far beyond tracking what’s on hand—they connect data across your entire operation, analyze patterns, and empower teams to make smarter, proactive decisions.

The Evolution of Inventory Management

To understand where we are today, it’s important to see how far inventory management has come.

From MRPs to Modern Intelligence

Traditionally, inventory-heavy businesses (especially manufacturers and distributors) relied on Material Requirements Planning (MRP) systems – tools that helped schedule production and ensure materials were available. While effective in their time, MRPs were often reactive rather than proactive. They could tell you when something went wrong, but not necessarily why, or how to prevent it next time.

These systems were also siloed – managing production but not always connecting with sales, procurement, or fulfillment. As a result, teams made decisions based on outdated or incomplete information.

The Modern Shift

Today’s inventory optimization software is no longer just a tool for tracking materials or balancing supply and demand — it’s a dynamic intelligence system that helps businesses make faster, more accurate, and more strategic decisions.

Modern solutions are designed around three core principles: intelligence, adaptability, and connection. They don’t just help manufacturing, distribution, and retail environments control what they already have – they enable teams to predict, plan, and pivot in response to changing market conditions.

What Modern Inventory Optimization Looks Like

The new generation of inventory optimization software is transforming operations for SMB manufacturers, distributors, retailers, ecommerce sellers, and hybrid businesses—helping them plan smarter, respond faster, and stay connected across production, purchasing, and sales channels.

Real-Time Visibility

In the past, businesses relied on periodic reports or manual data entry to understand what was happening on the shop floor. Today, that’s no longer enough. Modern systems provide real-time visibility into every stage of production and distribution.

This means they can instantly monitor stock levels across multiple warehouses, production lines, and sales channels — with live data updates instead of delayed snapshots. Real-time visibility allows decision-makers to spot discrepancies early, adjust production schedules on the fly, and respond to customer orders immediately. For growing SMBs, this level of transparency turns uncertainty into control. It ensures that inventory data is always accurate, up to date, and actionable — even as operations scale.

Predictive Insights

Forecasting has always been a challenge in manufacturing, especially for smaller companies that lack large analytical teams. Modern inventory optimization tools now integrate AI and machine learning to turn historical and real-time data into predictive insights.

Rather than reacting to changes after they happen, businesses can anticipate them – identifying potential demand surges, supplier delays, or stock imbalances before they disrupt operations. For example, if purchasing data shows extended supplier lead times or customer order trends indicate an upcoming demand spike, predictive models can alert teams early enough to make proactive adjustments. This ability to foresee and act ahead of time transforms inventory management from a defensive process into a strategic advantage.

Integrated Data

Disconnected systems have long been one of the biggest obstacles to efficiency. As data often lives in multiple places – ERP platforms, spreadsheets, accounting software, CRM tools, and production systems – making it difficult to gain a complete picture of what’s really happening.

Modern inventory optimization platforms solve this by offering data integration across all key business systems. They connect production planning, procurement, sales, and fulfillment into one unified dashboard, creating a single source of truth for all teams. This not only eliminates data silos but also enhances collaboration and accuracy. When everyone works from the same real-time information, decisions are faster, coordination improves, and costly misalignments between departments are reduced.

Automation

Manual reporting, data entry, and repetitive planning tasks have historically consumed hours of valuable time for manufacturers. Modern tools now embed automation at the core of their functionality, enabling businesses to eliminate inefficiencies and focus on higher-value work.

Automation can handle routine processes such as stock adjustments, reorder point updates, and performance reporting — ensuring that nothing falls through the cracks. AI-driven dashboards can even generate insights automatically, highlighting trends or anomalies that deserve attention without requiring constant human oversight.

For SMBs, automation is more than a time-saver; it’s a competitive equalizer. It allows small teams to operate with the efficiency and precision of much larger organizations, freeing up time for strategy, innovation, and growth.

Collaboration Tools

Business success depends on alignment—across production, procurement, sales, and fulfillment. When teams work in isolation or rely on outdated communication methods, even the best plans can fail. Modern inventory optimization software provides built-in collaboration tools that unify teams around shared data and goals. Whether it’s production schedules, procurement planning, or sales forecasting, everyone sees the same information and can act in sync.

This shift moves inventory management from reactive tracking to proactive, data-driven decision-making. Product-making businesses can now optimize operations holistically boosting efficiency, reducing waste, and enhancing customer satisfaction.

Challenges SMBs Still Face

Despite these advancements, many small and mid-sized manufacturers, distributors, retailers, ecommerce sellers, and hybrid businesses still struggle to take full advantage of modern inventory tools. The challenges often come down to resources, integration, and data quality.

Disconnected Systems

Inventory, production, and sales data are often stored in separate systems. Without integration, it’s difficult to see the big picture. One department might be producing too much of a product while another struggles to fulfill backorders — simply because the data doesn’t flow between them.

Time-Consuming Processes

Manual data entry, reporting, and spreadsheet management eat up valuable hours that could be spent on strategy, production, or innovation. Human error can also skew forecasts and cause misalignment between teams.

Forecasting Gaps

Traditional forecasting methods rely heavily on historical sales or gut instinct. But in a world where demand can change overnight — due to new trends, global events, or supply chain shocks — that approach just isn’t enough.

Operational Inefficiencies

The result of these gaps? Stockouts, overstocks, and delayed replenishments that hurt cash flow and customer satisfaction.

Katana + ConverSight: Taking Inventory Optimization to the Next Level

That’s where the combination of Katana and ConverSight comes in.

Visibility is critical — but visibility alone isn’t enough. Modern SMBs requires not only knowing what’s happening but understanding why it’s happening and what to do next.

Together, Katana and ConverSight bridge that gap — merging intuitive inventory management with AI-driven intelligence to help SMBs make faster, smarter, and more confident decisions.

Katana

Modern Inventory Optimization Software for Product-Based Businesses

Katana has long been recognized as one of the leading inventory management systems for Product-Based Businesses. And it’s much more than an MRP tool—it acts as a single source of truth for inventory that plugs seamlessly into your tech stack.

Katana connects production, sales, inventory, and purchasing into a single unified view, making it easy to manage operations for a variety of product-making businesses. Whether you sell primarily online, run outsourced or contract production, fulfill through multiple warehouses, or produce made-to-order, assemble-to-order, or batch-made goods, Katana brings clarity and control to every aspect of your workflow.

What Katana Delivers

- Unified Inventory Tracking: View and manage stock levels across multiple warehouses, sales channels, and production lines.

- Live Production Management: Balance production schedules with customer orders and material availability.

- Smart Resource Allocation: Automatically allocate raw materials to the right jobs at the right time.

- Reduced Waste: Prevent overproduction, minimize carrying costs, and improve order accuracy.

- Seamless Integrations: Connect easily with tools like Shopify, QuickBooks, and Xero to keep all data synchronized.

For growing businesses, this means less firefighting and more proactive, data-informed decision-making.

ConverSight

Adding AI Intelligence to Inventory Optimization

If Katana gives organizations clarity and control, ConverSight adds a powerful layer of intelligence.

ConverSight is an AI analytics and forecasting platform designed to help teams move from insights to action. With its intelligent assistant, Athena, users can interact with their data in natural language — asking questions like:

- “Which SKUs are trending low this week?”

- “What are the top reasons for delayed shipments?”

- “Where should I focus my replenishment next quarter?”

Key Capabilities

- AI Forecasting: ConverSight learns from historical and real-time data to generate highly accurate demand forecasts.

- Risk Detection: Identify potential supply bottlenecks or shortages before they impact production.

- Automated Insights: Replace manual reports with daily, AI-generated analytics delivered directly to your dashboard.

- Scenario Modeling: Simulate “what-if” situations — such as sudden demand spikes or supplier delays — to test your resilience.

When integrated with Katana, ConverSight turns visibility into foresight — helping manufacturers not just see what’s happening but predict what’s next.

The Shift in Inventory Optimization Software

For decades, SMB manufacturers have relied on traditional MRP (Material Requirements Planning) systems to manage materials and plan production. But today’s supply chains move faster, operate globally, and demand more flexibility than MRP alone can deliver.

Modern businesses are now shifting toward intelligent inventory optimization software — tools that provide real-time visibility, predictive insights, and adaptive planning. This evolution moves inventory management from reactive tracking to proactive decision-making.

Katana represents this new generation of software — designed for SMBs who need a connected, intuitive system to manage production, materials, and demand in one place.

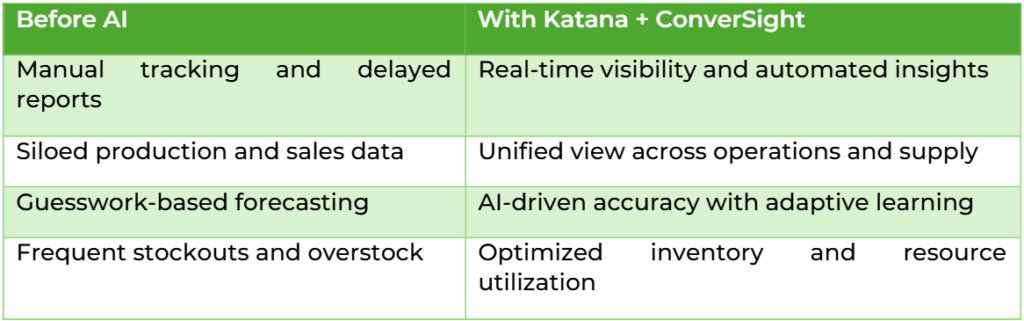

Here’s how the shift looks in practice:

This shift doesn’t just save time — it builds resilience, efficiency, and scalability into everyday operations.

Real-World Applications: What Smart Inventory Optimization Looks Like

The benefits of smarter inventory optimization are clear across a wide range of operations. Whether a company manufactures goods, sells online or in-store, distributes products, or manages complex supply chains—the combination of real-time visibility and AI-powered insights leads to measurable improvement.

Here are a few ways manufacturers are applying these capabilities in practice:

Example 1: Reducing Overstock and Freeing Up Capital

Many businesses hold excess materials or finished goods “just in case” of future demand. Modern inventory optimization provides the visibility and confidence needed to maintain optimal stock levels, reducing overproduction, freeing up working capital, and improving cash flow.

Example 2: Anticipating Demand Fluctuations

Seasonal patterns, market shifts, and sudden changes in customer behavior can cause major disruptions when forecasts rely only on past performance. AI-driven forecasting allows businesses to anticipate these fluctuations earlier, align procurement and production accordingly, and maintain service levels without carrying unnecessary inventory.

Example 3: Strengthening Supplier Collaboration

By connecting operational data across systems, businesses gain a clearer view of upcoming material requirements and production needs. This enables more effective communication with suppliers, better planning for lead times, and improved resilience against unexpected disruptions.

The Broader Impact: Sustainability and Resilience

Intelligent inventory optimization doesn’t just improve profitability — it supports sustainability and long-term resilience.

- Less Waste: AI-driven insights help reduce overproduction and excess materials.

- Efficient Transportation: Better forecasting means fewer emergency shipments and optimized logistics.

- Informed Sourcing: Data visibility enables smarter, more sustainable supplier choices.

By reducing overproduction and excess materials, optimizing logistics, and enabling smarter sourcing decisions, manufacturers, retailers, distributors, and sellers can lower their carbon footprint while maintaining growth.

Building the Future of Product Operations

The world is evolving, and SMBs are leading the charge with technology that gives them enterprise-level agility, visibility, and intelligence.

Katana and ConverSight together represent the next step in this evolution.

- Katana provides the clarity and control needed to manage day-to-day operations efficiently.

- ConverSight brings foresight, automation, and adaptability through AI-driven insights.

The result is a connected, intelligent, and scalable foundation for modern operations—where every decision is backed by data, processes are optimized, and every customer is served faster and more reliably.

The Takeaway

Inventory optimization isn’t just about keeping shelves filled — it’s about giving teams the clarity to plan smarter, move faster, and grow with confidence.

As digital transformation accelerates, SMB manufacturers, retailers, distributors, and sellers that adopt AI-driven tools like Katana and ConverSight will gain a decisive edge — turning complexity into control and volatility into opportunity.

Get Started

Transform how you plan, produce, and deliver with Katana and ConverSight.

Start building a smarter, more resilient operation — powered by visibility, intelligence, and innovation.