Challenges: Supply Chain Inefficiencies Impacting Margins and Customer Satisfaction

Koken USA, a leader in high-quality tools for industries like automotive and aerospace, faced significant operational challenges as their business rapidly expanded. Long ocean freight lead times and rising air freight costs caused stockouts and backorders, leading to delayed customer deliveries. Koken needed a solution that could provide predictive insights, optimize inventory, and streamline operations to maintain efficiency and customer satisfaction.

Solutions: Inventory and Supply Chain Management

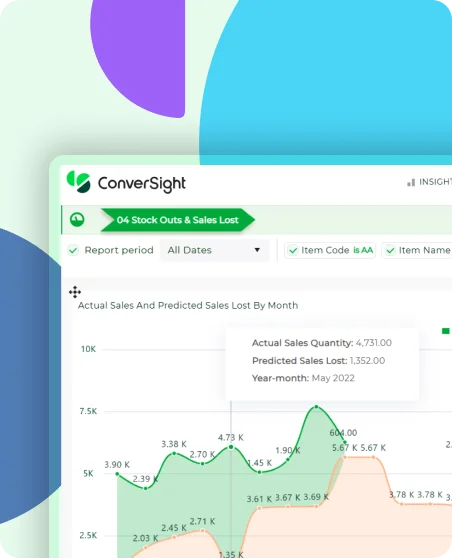

AI Sales Analytics

Predictive analytics revealed sales trends, optimizing backorders and proactive demand fulfillment.

Critical Parts Tracking

Advanced analytics suggested optimal reorder points, ensuring Koken maintained adequate stock levels.

Recommended PO

Intelligent analysis of historical sales, lead times, and trends optimized orders, lowering costs and sourcing complexity.

Forecast Seasonal Demand

Use historical data to predict seasonal requirements, optimize inventory and enhance supplier communication.

ConverSight Supply Chain Intelligence

| Before ConverSight | After ConverSight |

| Frequent stockouts and backorders due to long lead times | Predictive analytics enabled better demand planning and proactive fulfillment |

| Rising freight costs from rushed and unplanned shipments | Optimized ordering helped reduce urgent shipping needs and associated costs |

| Manual processes struggled to manage growing inventory complexity | Intelligent reorder suggestions streamlined procurement and inventory control |

| Lack of visibility into seasonal trends and part-level demand | Historical trend analysis improved forecasting and supplier coordination |

With ConverSight and Fishbowl, we’re not just managing inventory—we’re predicting it. This transformative solution has taken our operations to the next level.

Kathleen Kautz, Operations Manager, Koken USA

Industry

Industrial Machinery and Equipment

Company Type

Private

ERP

Fishbowl Inventory