Introduction

Supply chains today operate in a highly connected, complex, and data-intensive environment. With global sourcing, heightened customer expectations, and multichannel operations, what was once a linear and siloed process has evolved into a dynamic, interdependent ecosystem. However, this advancement comes with challenges—without centralized visibility and control, disruptions escalate, inefficiencies persist, and competitiveness erodes.

Traditional tools such as spreadsheets, outdated systems, and isolated applications are no longer sufficient. They lack the integration, automation, and intelligence required to respond with speed and precision. This is where Enterprise Resource Planning (ERP) becomes essential. ERP systems introduce structure, real-time visibility, and process automation across supply chain functions. More than just streamlining tasks, ERP empowers teams with the insights needed for faster, more informed decision-making.

In this blog, we’ll explore how ERP transforms supply chain management, the strategic advantages it delivers to businesses, and how platforms like ConverSight are enhancing ERP capabilities with AI and automation.

Why ERP Is Critical for Modern Supply Chains

Modern supply chains are made up of many moving parts—procurement, inventory, production, warehousing, logistics, order fulfillment and finance. In many organizations, each of these functions is handled through separate systems or tools, often developed in isolation. Procurement may run on one platform, inventory on another, logistics through spreadsheets or third-party apps, and financials in separate accounting software. This lack of integration creates fragmented workflows and data silos.

Such fragmentation leads to serious challenges:

- Blind spots in operations due to limited data sharing between departments

- Inefficiencies caused by manual updates and duplicated work

- Lack of coordination, where decisions in one department don’t align with another

- Firefighting mode, where teams react to issues instead of preventing them

An ERP (Enterprise Resource Planning) system addresses these issues by serving as the central nervous system of the supply chain. It connects all key functions—procurement, inventory, production, logistics, and finance—within a single unified platform. This integration ensures that information flows seamlessly across departments, enabling cross-functional visibility and real-time decision-making.

| With ERP | Without ERP |

| Procurement gets real-time inventory updates to avoid overstocking or shortages | Procurement decisions are delayed due to outdated or disconnected inventory data |

| Production planning aligns with material availability and order priorities | Production faces bottlenecks due to misaligned materials and unclear priorities |

| Logistics has access to accurate order and shipment data | Logistics struggles with delays and errors from manual or siloed tracking |

| Finance can track costs, margins, and cash flow from a supply chain perspective | Finance lacks visibility into supply chain costs, affecting profitability tracking |

| Unified data ensures synchronized, end-to-end operations | Disjointed systems create data silos and hinder collaboration |

| Decisions are proactive and based on real-time insights | Decisions are reactive and often based on incomplete information |

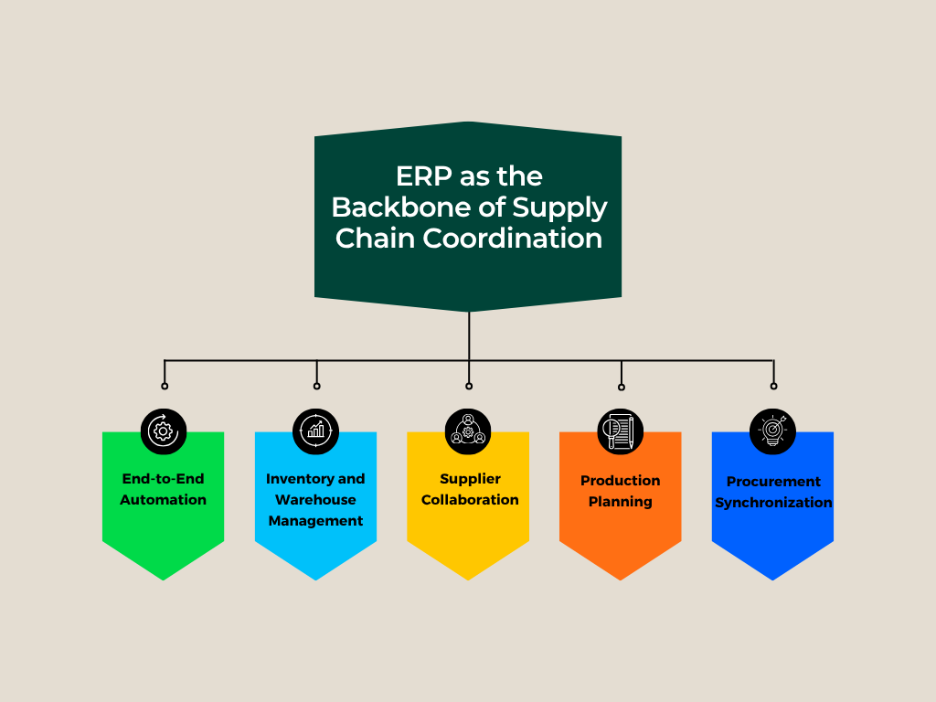

What ERP Really Solves in the Supply Chain

ERP systems do far more than simply digitize supply chain tasks—they coordinate and connect every stage of the process into a single, seamless workflow. By acting as a centralized platform, ERP enables better planning, communication, and execution across departments.

End-to-End Automation

ERP automates routine, repetitive tasks throughout the supply chain. This includes everything from generating purchase requisitions and processing approvals to creating invoices and matching them with goods received. Automation reduces manual errors, speeds up workflows, and ensures that key processes don’t fall through the cracks.

Inventory and Warehouse Management

An ERP system provides real-time visibility into stock levels across multiple locations. It helps track inventory movement, allocate items efficiently, and trigger replenishment when levels drop below thresholds. This improves inventory accuracy, reduces holding costs, and prevents both overstocking and stockouts.

Supplier Collaboration

ERP facilitates better communication and coordination with suppliers by centralizing purchase orders, delivery schedules, and performance data. Businesses can monitor vendor reliability, lead times, and compliance, making it easier to manage supplier relationships and hold vendors accountable for delays or quality issues.

Production Planning

Manufacturing processes rely heavily on timing and material availability. ERP systems align production schedules with inventory levels and order demand, ensuring that raw materials are available when needed and that resources are utilized efficiently. This minimizes downtime, avoids bottlenecks, and keeps production on track.

Procurement Synchronization

With ERP, procurement decisions are directly informed by demand forecasts, stock levels, and sales trends. This helps prevent overordering or underordering and ensures that purchasing is aligned with actual business needs. It also allows for better negotiation and planning with suppliers based on consolidated purchasing data.

Logistics and Reverse Logistics Visibility

ERP enables real-time tracking of outbound shipments, deliveries, returns, and even reverse logistics processes. This visibility helps logistics teams coordinate more effectively, respond to delays quickly, and keep customers informed. It also improves accuracy in returns processing and inventory reconciliation.

The Promise of AI-Powered ERP

Modern ERP systems have evolved beyond basic automation. With the integration of artificial intelligence (AI) and machine learning, ERPs now offer intelligent capabilities that help businesses do more than just track operations—they enable proactive, data-driven decisions. AI-powered ERPs analyze historical trends, real-time data, and external signals to provide predictive insights and automate routine actions. Instead of simply recording events like stockouts or sales fluctuations, these systems can anticipate them and recommend or execute responses ahead of time.

For example, they can forecast demand with higher accuracy, suggest optimal pricing based on market trends, or automatically reorder materials when inventory runs low. This marks a major shift from manual data entry and static workflows to automated, intelligent operations. The result is a supply chain that’s not only efficient but also responsive, adaptive, and resilient. AI-powered ERP helps organizations reduce errors, improve planning, and make faster, more informed decisions at every level of the supply chain.

Key Benefits of AI-Powered ERP

- Predictive insights: Anticipates issues like stockouts or delivery delays before they occur.

- Automated decision-making: Uses real-time data to trigger actions like reordering or adjusting schedules.

- Accurate demand forecasting: Improves inventory planning and reduces overstock/stockout risks.

- Dynamic pricing and promotions: Adjusts strategies based on market trends and consumer behavior.

- Intelligent workflow triggers: Initiates processes automatically based on data patterns (e.g., reorder points, delays).

- Real-time exception handling: Detects and responds to anomalies immediately to minimize impact.

- Enhanced responsiveness: Reduces guesswork and increases supply chain agility.

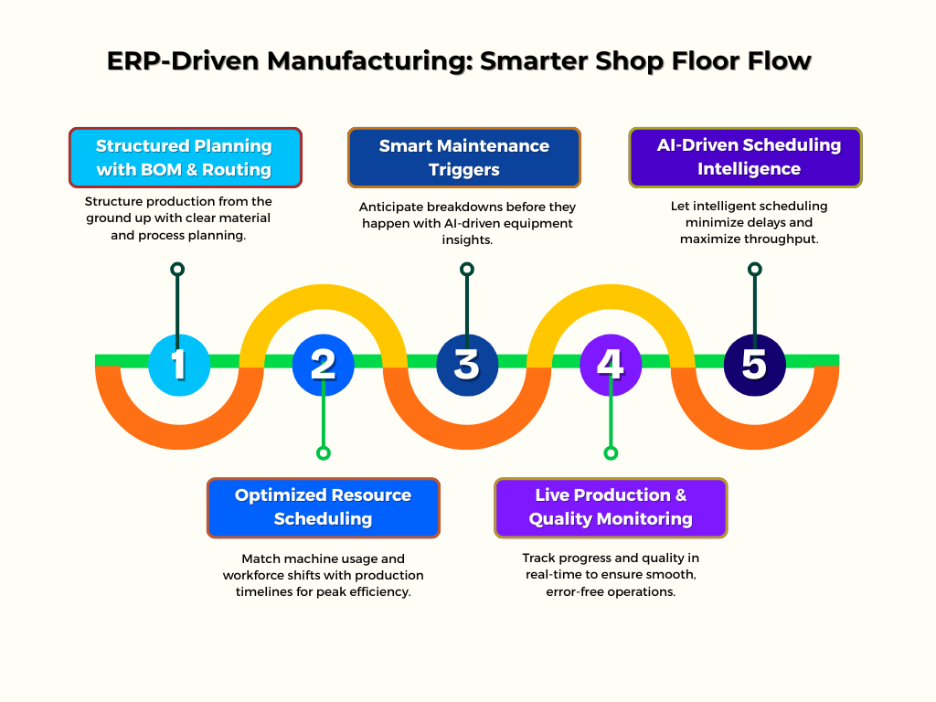

ERP for Manufacturing

In manufacturing, efficiency, precision, and coordination are critical. ERP systems play a key role in aligning shop floor activities with broader business objectives. By bringing together data from production, inventory, procurement and planning, ERP systems ensure that manufacturing operations are well-coordinated, cost-effective, and responsive to changing demands.

- Bill of Materials (BOM) & Routing

ERP manages detailed BOMs and production routing, ensuring accurate planning and tracking of materials and processes.

- Machine Utilization & Workforce Scheduling

It helps optimize the use of machinery and workforce by aligning production schedules with capacity and shift availability.

- Predictive Maintenance

By analyzing equipment data, ERP systems can anticipate potential failures and schedule maintenance to reduce unplanned downtime.

- Real-Time Production Tracking & Quality Checks

ERP provides visibility into production progress and integrates quality control checks to catch issues early.

- AI-Powered Intelligent Scheduling

With AI enhancements, ERP systems can optimize production runs, reduce changeovers, and improve overall efficiency on the shop floor.

In essence, ERP connects what’s happening on the shop floor to strategic business goals, enabling manufacturers to produce smarter, faster, and with greater precision.

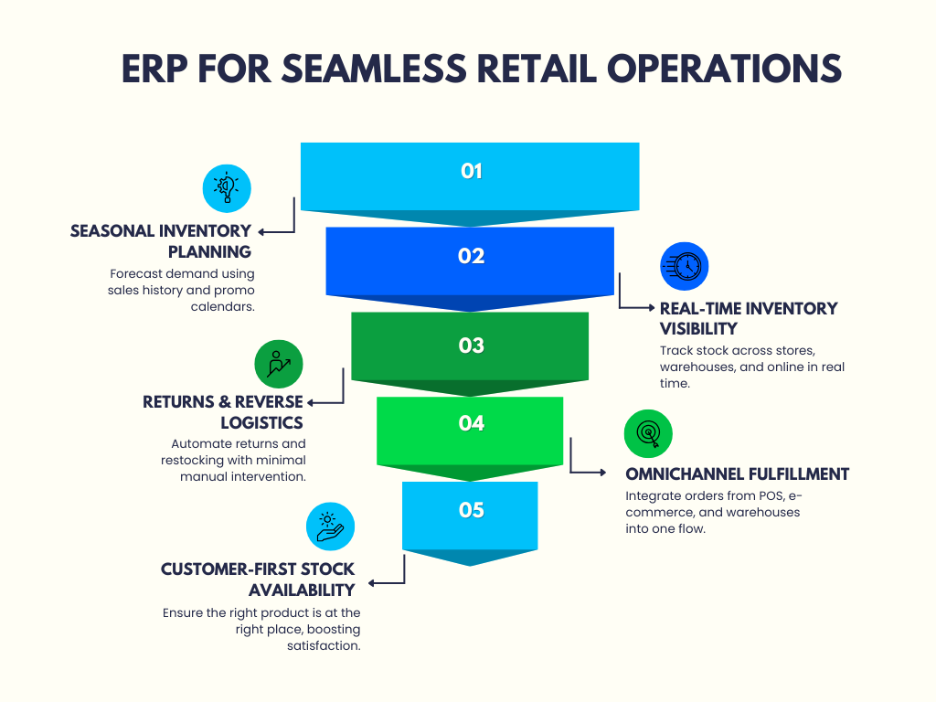

ERP for Retail

Retail supply chains operate in fast-paced, customer-driven environments, requiring high responsiveness and visibility. ERP systems address these needs by supporting the following:

- Seasonal Inventory Planning & Promotion-Based Forecasting

ERP helps retailers anticipate seasonal demand spikes and align inventory levels accordingly. It uses historical sales data and promotional calendars to forecast product needs, ensuring shelves are stocked during peak periods without overcommitting capital to slow-moving items.

- Real-Time Visibility Across Stores, Warehouses & Online Channels

A retail ERP provides a centralized view of inventory, allowing teams to track stock movement across multiple locations in real time. This visibility ensures better stock allocation, reduces discrepancies, and helps prevent both overstock and stockouts, especially during high-traffic sales periods.

- Returns Management & Reverse Logistics Coordination

Returns are a critical part of the retail cycle, especially with online shopping. ERP systems streamline return processing, automate refunds or replacements, and update inventory accordingly. They also track reverse logistics to ensure returned items are inspected, restocked, or disposed of properly.

- Omnichannel Order Fulfillment

ERP systems integrate with point-of-sale (POS), e-commerce platforms, and warehouse systems to manage orders from all channels in one place. Whether a customer orders online for home delivery or picks up in-store, ERP ensures a seamless fulfillment process with accurate inventory and timely dispatch.

- Customer-Centric Stock Availability

By syncing inventory with demand and fulfillment processes, ERP ensures that products are available where and when customers need them. This reduces lost sales opportunities, increases customer satisfaction, and improves brand loyalty across digital and physical channels.

A well-implemented ERP system allows retailers to operate with agility, adapt to changing demand, and provide a consistent, high-quality customer experience across all touchpoints.

Choosing the Right ERP for Supply Chain

An ERP isn’t just a software investment—it’s the backbone of how your supply chain runs. And choosing the right one can mean the difference between agility and inefficiency.

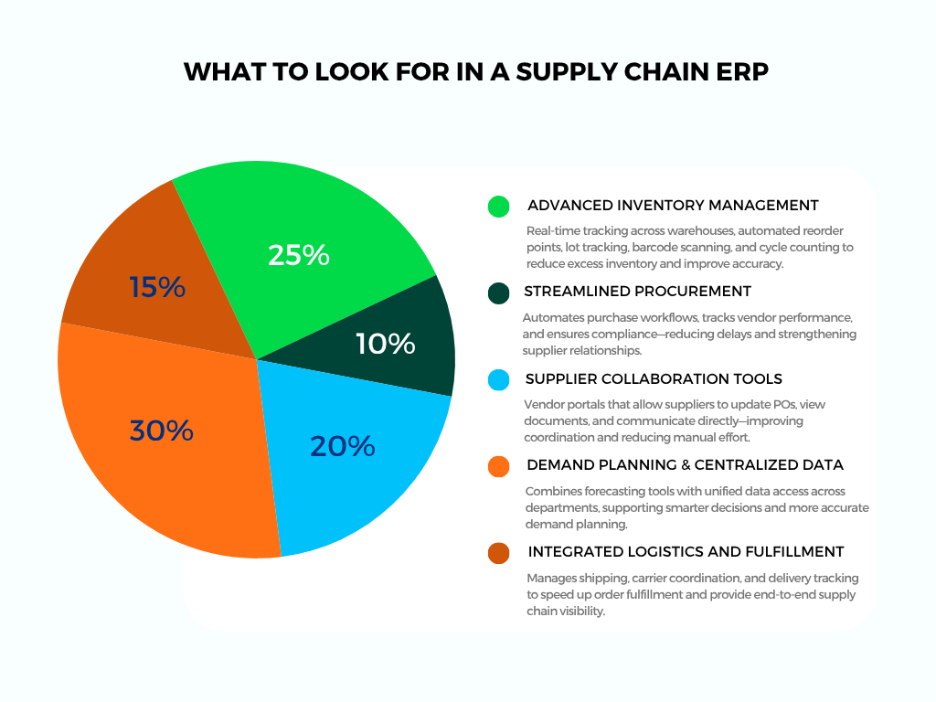

What to look for in a Supply Chain ERP

At the core, the ERP must offer strong, built-in capabilities for inventory management, procurement, logistics coordination, and supplier collaboration. These are the operational pillars that keep your supply chain responsive and cost-effective. Without them, teams often resort to manual workarounds or disconnected tools that slow processes and increase errors.

- Inventory management tools should allow you to track stock across multiple locations in real time, manage reorder levels, and prevent both overstock and stockouts.

- Procurement modules must streamline purchasing with supplier catalogs, approvals, and contract management features, ensuring timely and compliant sourcing.

- Logistics functionality should include tools for managing shipments, carriers, and delivery tracking, enabling visibility across the fulfillment lifecycle.

- Supplier portals or vendor collaboration platforms ensure smoother communication, faster onboarding, and better performance tracking.

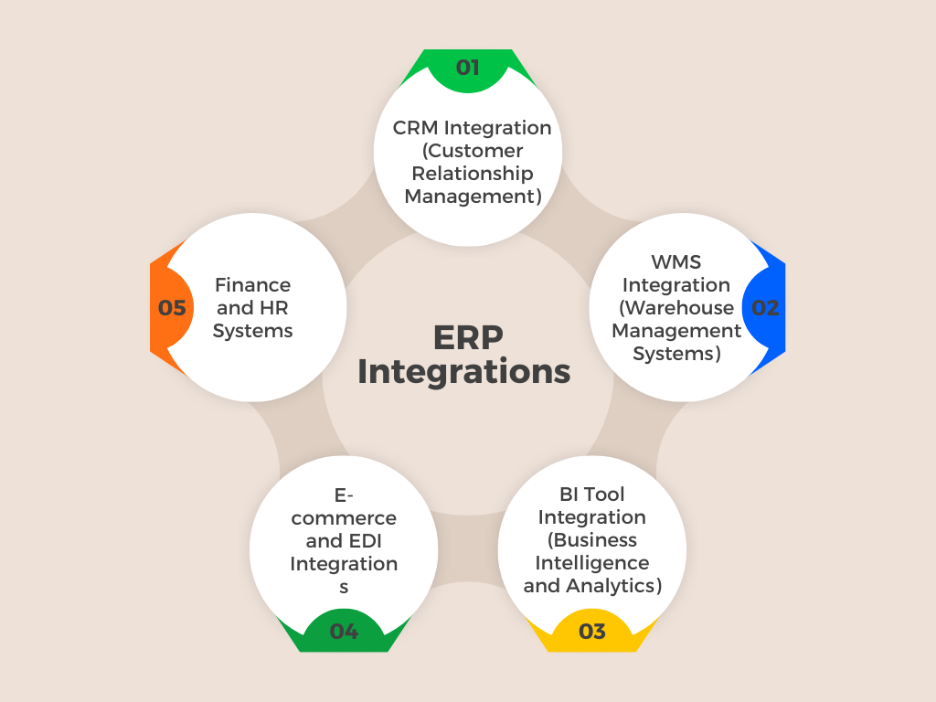

Integration Isn’t Optional

Modern supply chains rely on connected systems. That’s why integration is not a nice-to-have—it’s a must-have. Your ERP should seamlessly connect with the rest of your tech stack to ensure real-time visibility and coordination across departments.

Here’s what to prioritize:

CRM Integration (Customer Relationship Management)

Syncing your ERP with a CRM system ensures that customer and sales data flow both ways. This allows your teams to align inventory with demand, personalize service, and manage sales orders more accurately.

WMS Integration (Warehouse Management Systems)

A direct link with WMS platforms allows for tighter warehouse control—from inbound receiving to outbound shipping. This helps automate picking, packing, cycle counts, and improves stock accuracy across multiple locations.

BI Tool Integration (Business Intelligence and Analytics)

Your ERP must feed data into BI tools to enable advanced reporting and dashboards. This allows decision-makers to track KPIs, spot inefficiencies, and uncover trends that drive continuous improvement.

E-commerce and EDI Integrations

For retail or B2B businesses, ERP connections with e-commerce platforms and EDI systems streamline order processing and minimize manual entry, ensuring faster, more accurate fulfillment.

Finance and HR Systems

Integrating financials and HR tools with your ERP provides a single source of truth for budgeting, payroll, cost tracking, and workforce planning—creating a fully unified business environment.

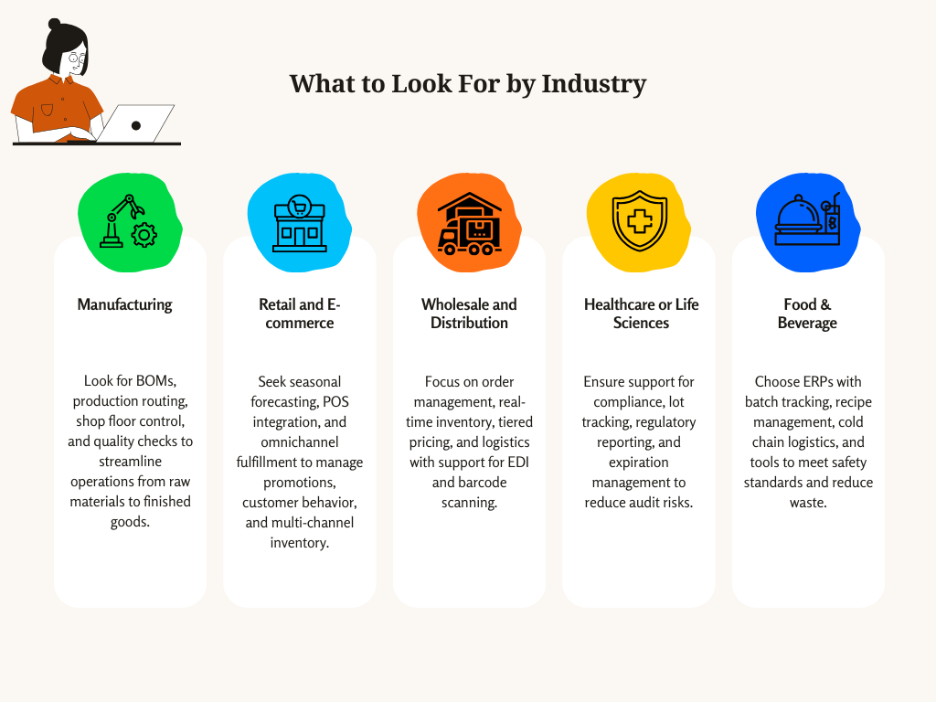

Industry-Focused = Less Customization

Selecting an ERP tailored to your industry minimizes the need for complex customizations. A solution built with your sector in mind comes equipped with relevant workflows, terminology, and compliance support—reducing implementation time and cost.

Manufacturers need features like BOMs, routing, and shop floor control. Retail businesses benefit from seasonal planning and omnichannel fulfillment capabilities. The closer the ERP fits your operational model, the faster your teams can adopt it, and the less you’ll spend modifying or building custom modules. A purpose-built ERP brings immediate alignment with your core processes.

Implementation Pitfalls to Watch For

ERP implementation is more than deploying software—it reshapes how an organization functions. Many projects fail not because of the system, but due to overlooked details during execution.

Key pitfalls include:

- Data Migration Gaps: Moving data from legacy systems without cleaning or validating it leads to inconsistent reporting and operational issues. Historical inaccuracies or missing fields can undermine confidence in the new system from day one.

- Master Data Confusion: If different departments have varying definitions for products, customers, or vendors, it creates discrepancies across workflows. Centralized governance for master data is critical to avoid silos.

- Ignoring Change Management: New systems bring new processes. Without proper training and communication, employees may resist the change or revert to old methods—slowing adoption and reducing ROI.

- Over-Customization: While tailoring the ERP to fit existing processes may seem helpful, it often complicates upgrades, increases maintenance, and drifts from best practices. It’s better to adapt to standard features when possible.

- Lack of Executive Sponsorship: ERP rollouts require top-down support. When leadership is disengaged, priorities get lost, and teams may lack the motivation or resources to follow through.

Supercharging ERP with ConverSight

Already running a robust ERP system but still grappling with reporting ConverSight enhances your ERP by adding a powerful layer of AI, automation, and conversational analytics that works with your existing systems—not against them. It’s like giving your ERP an upgrade without downtime or disruption.

Rather than relying on static reports or waiting on IT teams, ConverSight empowers users with instant answers and guided decisions. It acts as an AI-powered co-pilot, enabling business leaders to ask natural-language questions and receive context-aware insights pulled directly from ERP data.

ConverSight provides:

- Conversational Insights

Skip the dashboards and spreadsheets. Ask questions like “Which SKUs are driving the highest returns?” or “Why did Q3 revenue drop in the Southeast region?” and get clear, visual responses in seconds.

- AI Forecasting

Replace guesswork with machine learning that analyzes historical trends, seasonality, and external factors to anticipate demand and avoid disruptions.

- Automated Reports

Eliminate repetitive reporting tasks by turning complex Excel-based workflows into automated, real-time dashboards accessible anytime, anywhere.

- Supply Planning

Get proactive purchase recommendations that help maintain optimal inventory levels while minimizing excess and stockouts—no spreadsheets needed.

- Finance & Sales Intelligence

Access plug-and-play dashboards that track working capital, revenue trends, customer segments, and sales performance—ready to go live within days.

| ERP Limitations | ConverSight Enhancements |

| Reporting is manual and time-consuming, often dependent on Excel or IT teams. | Reports are automated and instantly available as dynamic dashboards. |

| Data is scattered across modules and difficult to analyze quickly. | ConverSight centralizes ERP data and provides instant, context-aware insights. |

| Forecasting relies on static trends and gut feeling. | AI-powered models forecast demand, identify risks, and optimize planning. |

| Teams struggle with decision delays due to lack of real-time data. | Business leaders ask natural-language questions and get real-time answers. |

| Each department creates its own reports, leading to inconsistent KPIs. | Standardized reporting ensures consistent, cross-functional metrics. |

| Custom development is required to build any new dashboard or view. | Pre-built templates go live in days without custom coding. |

Conclusion

ERP has evolved from a transactional backbone into a strategic engine for supply chain excellence. It brings together procurement, inventory, logistics, and finance into a single system—enabling efficiency, visibility, and control across the value chain.

However, implementation alone isn’t enough. To truly maximize ROI, organizations must go beyond the basics. By layering AI, automation, and conversational analytics on top of ERP, businesses can turn static data into dynamic, decision-ready intelligence. Explore how ConverSight’s AI-driven platform brings automation, real-time insights, and smarter decisions to your supply chain.