Proactive insights to minimize Supply Chain disruption and improve productivity

In a fast-paced world, manufacturing is constantly experiencing change. Every business aims to improve productivity by minimizing disruptions and gaining insights. According to MHI- Deloitte research that surveyed 1000 organizations, 74% of the leaders have expressed shortages and supply chain disruption as an extreme to very extreme risk. As supply and demand variations continue to impact manufacturing abilities, businesses are striving to gain clearer visibility on inventory and distribution to gain transparency on operations.

The Problem

Asia’s growing commercial vehicle manufacturer, specializing in the delivery of 10,000+ parts from both domestic and international suppliers to manufacture world-class trucks, came to ConverSight wanting to gain better visibility on inventory, to automate manual processes, reporting and tracking, triggering a critical shift in digital transformation initiatives and improved visibility to our entire end-to-end Supply Chain process.

The main goal was to gain insight on Transparency on critical components in real-time and eliminate any unforeseen disruptions in production planning to mitigate risks across the supply chain.

Challenges Faced

The customer created a manual process that allowed for a quick assessment of materials risk against short-term production plans. The process soon became a vital input for planning and controlling the entire production of the company. The company relied heavily on a report called “Critical Parts Summary”. With so much attention going toward the report for the entire SCM and production team, challenges were faced with execution in the absence of the report.

Solution

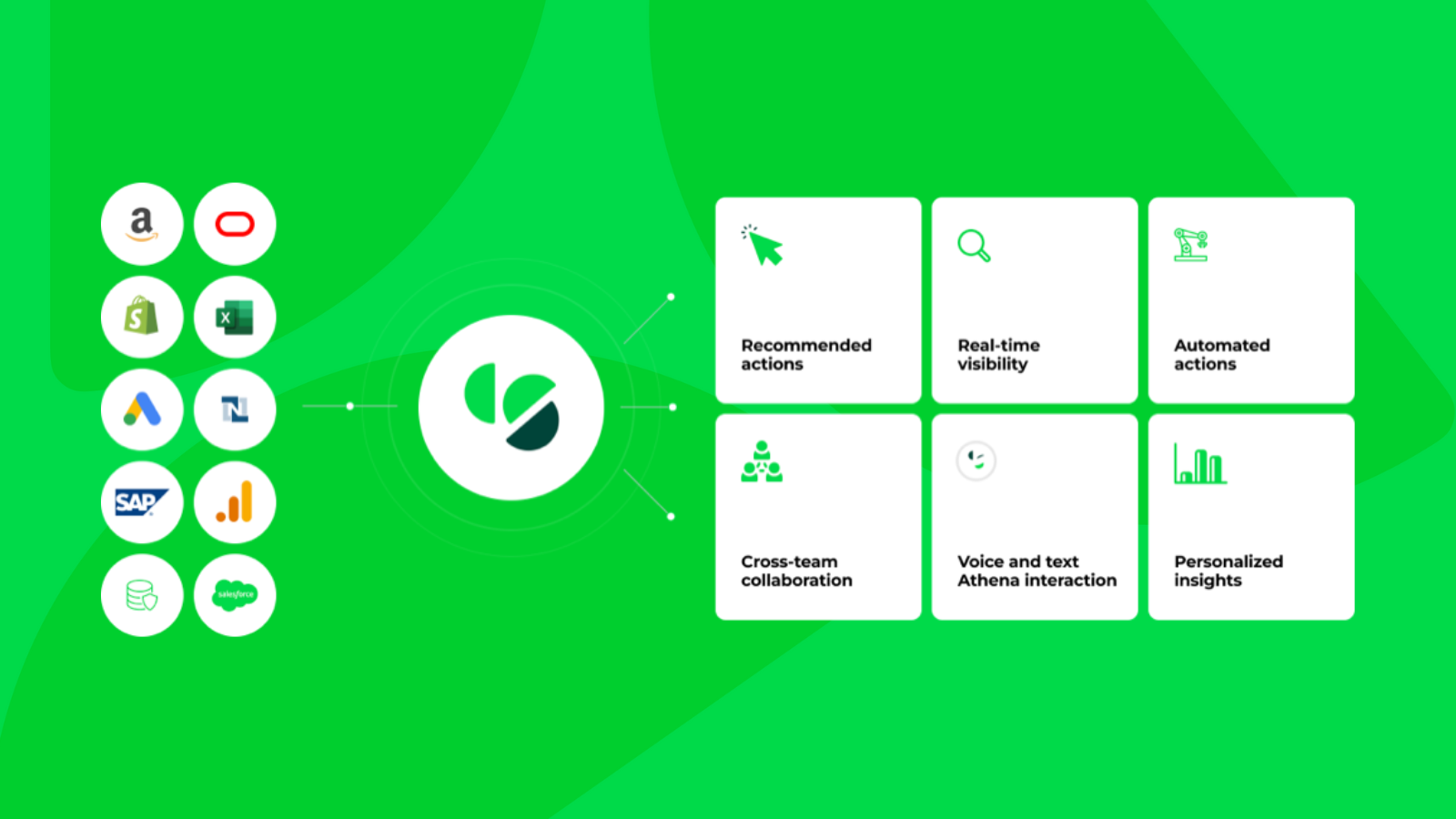

ConverSight delivered a well-executed plan to achieve more visibility, empowering the team to make quicker decisions and enable more agile and intuitive supply chain operations. ConverSight’s search and analytic technology allowed for an unscripted journey. This meant users could ask real-time questions and receive accurate data insights. ConverSight’s intelligent assistant, Athena, incorporates machine learning, data science, and cognitive techniques to deliver personalized insights and actions to understand user behavior, context, and intent of the conversation.

- Proactive Insights to streamline production

Insights around changes in demand for parts and shipment delays to proactively identify shortages and analyze on-hand, allocated, and on-order inventory along with demand forecasts

- End-to-End Visibility Visibility

Higher visibility for distributed teams like sourcing, procurement, operations, logistics, and sales to proactively get alerts on potential delays due to unavailability of critical parts and supplier delays

- Built-On Supplier Risk Analysis

Analyze the reliability of the supplier to meet the expected lead time for the part to coordinate its arrival and inform the decision to stock the item as part of the inventory

Results

With the implementation of ConverSight into the manufacturing processes, customer gained not only tremendous visibility and diverse analytics but overall productivity.

- The time that the organization spent weekly on analytics was reduced by nearly 110 hours per week.

- The amount of time it took for the organization to make a decision decreased by more than 60% because of instant insight and data availability.

- The alignment of the stakeholder saw a shift from manual and time-consuming to automated and instantaneous.

- Lastly, there was high flexibility of contextual analytics which allowed stakeholders to focus on what really mattered.

Ultimately, through ConverSight’s proactive insights that streamlined production, end-to-end visibility, and built-in supplier risk analysis, ConverSight was able to improve the functionality and efficiency of the organization to proactively mitigate risk and alert division makers with real-time inventory information.

To learn how ConverSight can help your business’s success soar request a demo or email [email protected] for more information!