AI Employee Supply Chain

From Spreadsheets to Smart Decisions

If you’ve ever worked in supply chain operations, you’ve probably lived this story: you open your laptop on a Monday morning to find three urgent emails about delayed shipments, two vendor calls asking for updated forecasts, and a spreadsheet that hasn’t been updated in days. You spend the next few hours piecing together data from ERP reports, supplier portals, and a flurry of Slack messages — just to figure out where you stand today. The problem isn’t just the workload. It’s the fact that decisions are made based on outdated, incomplete, or manually compiled data. Even the best teams are forced into firefighting mode, reacting to problems instead of preventing them.

Enter the AI Employee — not a chatbot that simply answers questions, but a tireless, digital operations manager that monitors your supply chain 24/7, predicts what’s coming next, and takes action before you even know there’s an issue. It’s the difference between reacting to a crisis and avoiding it entirely.

Meet Your New Supply Chain Teammate: The AI Employee

So, what exactly is an AI Employee?

In plain terms, it’s a digital worker that connects directly to your ERP, warehouse management system (WMS), and supplier data streams to make smart, proactive decisions. Unlike traditional automation tools or bots that follow rigid rules, an AI Employee learns from your data patterns, adapts to changes, and executes tasks from start to finish without constant human oversight.

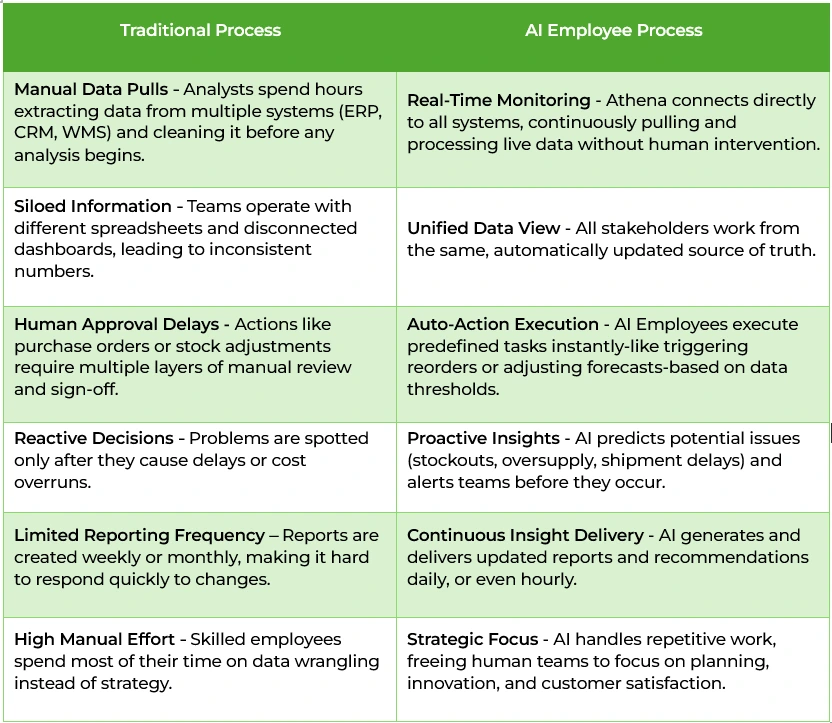

Here’s what sets an AI Employee apart:

- Proactive, not reactive: It doesn’t just wait for you to ask. It monitors your operations and flags or resolves issues in real time.

- Context-aware decision-making: Instead of following static rules, it considers current market trends, supplier lead times, seasonal spikes, and historical data before taking action.

- Cross-functional execution: It works across forecasting, purchase order generation, inventory optimization, and supplier management — just like a skilled operations manager would.

Imagine having a teammate who never sleeps, never misses a deadline, and never needs to dig through spreadsheets. That’s the value of an AI Employee.

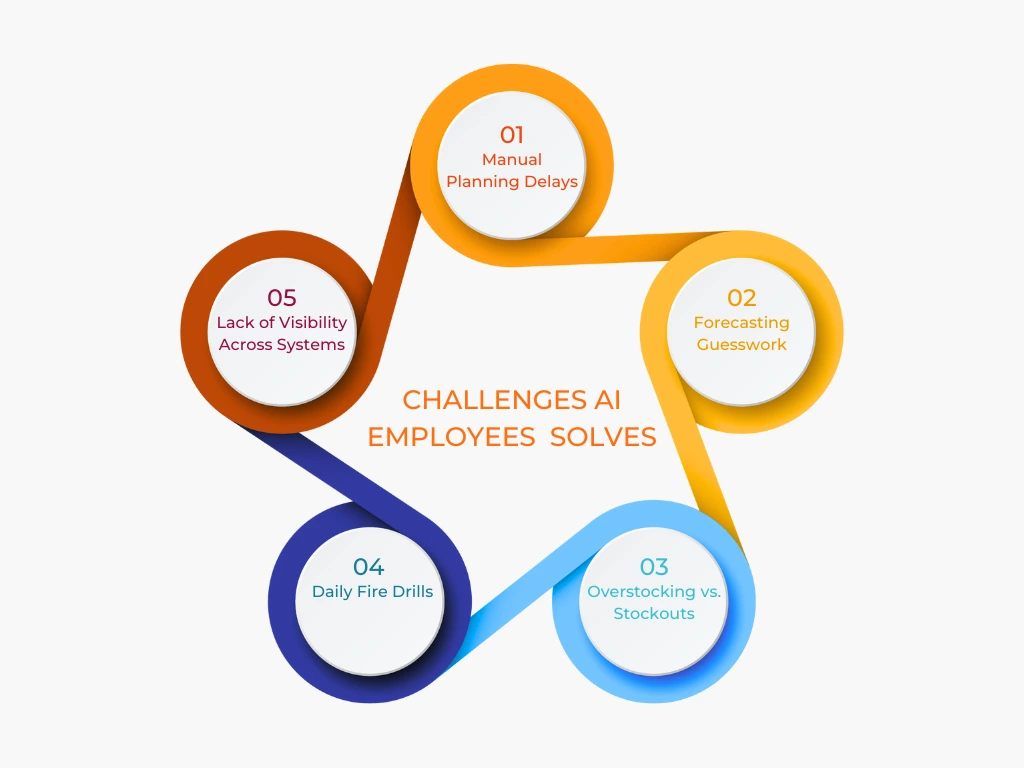

The Real Supply Chain Problems It Solves (and Why It Matters)

Running a supply chain without intelligent automation is like driving a car with your eyes half-closed — you might get to your destination, but the risks are high, and the ride is stressful. Here are the biggest challenges AI Employees are designed to solve:

- Manual Planning Delays

Planning meetings often start with outdated reports. By the time the data is compiled, market conditions may have already shifted.

- Forecasting Guesswork

Many teams rely on static forecasts created at the start of the year, ignoring changes in demand patterns, promotions, or external events.

- Overstocking vs. Stockouts

Overstock ties up working capital, while stockouts lead to missed sales and unhappy customers. Balancing the two manually is a constant headache.

- Daily Fire Drills

Most managers spend their days reacting to crises — late shipments, unexpected demand spikes, or sudden supplier issues — instead of focusing on strategy.

- Lack of Visibility Across Systems

Data lives in silos: ERP, WMS, supplier portals, and spreadsheets. Without a central intelligence, connecting the dots is slow and error-prone.

How AI Employees Handle the Heavy Lifting

An AI Employee isn’t just another dashboard that tells you what’s wrong — it’s an active problem-solver that takes care of the grunt work. Here’s how:

- Monitor Inventory and Trigger Alerts

The AI Employee tracks stock levels in real time, identifying trends like unexpectedly fast-selling SKUs or slow-moving items clogging up warehouse space.

- Predict Demand with Real-Time Data

It combines historical sales data, current orders, market trends, and supplier lead times to create forecasts that update automatically as conditions change.

- Recommend (or Place) Purchase Orders

Instead of simply telling you “Inventory is low,” it calculates the optimal reorder quantity, selects the preferred supplier, and can even place the order automatically.

- Consolidate Insights Across Systems

Pulling data from ERP, WMS, CRM, and supplier APIs, it delivers one unified view — no more jumping between tabs to piece together the full picture.

- Automate Reporting and Team Updates

Daily reports, vendor scorecards, and forecast updates can be auto-generated and sent to stakeholders without anyone lifting a finger.

The result? Teams spend less time chasing numbers and more time making strategic decisions.

Inside ConverSight’s AI Employee: Built for Supply Chain Pros

At ConverSight, we call our AI Employee Athena—a decision intelligence assistant tailored for operations and supply chain leaders. Moreover, Athena isn’t just connected to your ERP; she is woven into your daily workflows, providing actionable insights right at the point of need. Thus, whether in purchasing, planning, sales operations, or warehouse management, Athena helps make every process smoother, faster, and more accurate.

What makes Athena different:

- Plug-and-play integration: Works with popular ERP, CRM, and BI tools without heavy IT lift.

- Business-ready insights: No more raw data dumps — Athena translates numbers into clear recommendations.

- Cross-department impact: Supports supply chain, finance, and sales simultaneously for better alignment.

- Continuous learning: The more Athena works with your data, the better her recommendations get over time.

Download the Athena Whitepaper to see how AI-driven decision intelligence transforms supply chains.

What Real Businesses Are Achieving with AI Employees

The impact of AI Employees isn’t theoretical — it’s measurable.

Case Study 1: House of Spices – Smart Forecasting, Less Waste

In one of Asia’s largest spice companies, managing thousands of SKUs—many of them perishable—was a forecasting nightmare. Fortunately, Athena’s AI models revolutionized their operations by delivering three parallel forecasts (sales team projections, AI-driven forecasts, and actuals), which allowed the procurement team to better manage seasonal spikes and minimize waste. As a result, forecast accuracy improved by 30%, and inventory waste dropped by 20%.

“By continuously analyzing SKU-level data, we can now make better decisions and optimize our supply chain planning. The improvements we’ve seen in forecast accuracy are game-changing.” – Ruby Gangwar, Senior Planning Manager, House of Spices

Case Study 2: Motherson – Unified Data, Faster Decisions

Motherson, a $12 billion global automotive components manufacturer, struggled with fragmented data across ERP, logistics, and finance systems, making it challenging to gain real-time visibility and act quickly.

To address this, Athena connected these disparate sources into a single, reliable dashboard, eliminating silos and empowering teams with instant, accurate insights.

Consequently, reporting efficiency improved by 70%, MIS coverage expanded by 80%, and coordination time dropped by 40%—unlocking faster decisions and millions in savings.

“With Athena AI, we delivered our first use case in under three months. The speed and flexibility have transformed the way we manage our supply chain.” – Gaurav Gulati, Chief Information Officer, Motherson

Case Study 3: Extract Production – Data Overload to Insights in Minutes

An industrial equipment supplier was drowning in data: over 700 Fishbowl Inventory tables disconnected from Power BI, with no easy way to report. Athena made sense of the chaos- automating analytics, dashboards, and insights through no-code AI. Analytics costs dropped by 90%, insights were delivered 5× faster, and business users gained complete data autonomy – without needing technical expertise.

“Hiring Athena has jump-started a long-awaited digital-transformation initiative that is changing the way our entire organization views supply chain, planning and selling.” – Steve Carpenter, Supply Chain, Logistics and QMS

Why AI Employees in Supply Chain Are Now – Not the Future

It’s tempting to think AI Employees are part of some distant, futuristic vision. The truth? They’re already here — and the businesses using them are pulling ahead.

AI Employees don’t replace people; they amplify them. Instead of replacing supply chain managers, they give them the tools to be more strategic, agile, and impactful.

Think of it this way: while your competitors are still waiting for weekly reports, you’re acting on insights delivered in real time. While they’re hiring extra staff to handle seasonal spikes, you’re using AI to optimize workloads without adding headcount.

With platforms like ConverSight, adoption is fast and straightforward — no long implementation cycles, no massive retraining efforts.

Ready to see how AI Employees can transform your supply chain? Explore our AI Employee solution to discover its capabilities, real-world success stories, and how you can get started today.