A step-by-step guide for using AI to eliminate stockouts, cut costs, and scale smarter.

Challenge Statement

“43% of businesses miss sales due to poor inventory forecasting.” That’s nearly half of organizations leaving money on the table, losing not only revenue but also customer trust. In today’s hyper-competitive marketplace, where buyers expect instant availability and seamless fulfillment, stockouts and overstocks can make or break a brand’s reputation.

So, let’s pause and ask: What if you could predict exactly what to stock, where, and when? What if instead of reacting to demand fluctuations, you could anticipate them with precision? That’s where AI Inventory Forecasting comes into play.

Traditional forecasting relies on spreadsheets, static models, and gut instinct. But these approaches buckle under the weight of volatile markets, shifting consumer behaviors, and global supply chain disruptions. AI, on the other hand, thrives in complexity. By analyzing patterns, learning from data, and adjusting in real time, AI brings an unprecedented level of foresight to inventory planning.

This blog lays out a 5-step playbook for mastering AI-driven inventory forecasting—helping you eliminate stockouts, cut costs, and create a supply chain that grows smarter with every decision.

Step 1 – Gather the Right Data First

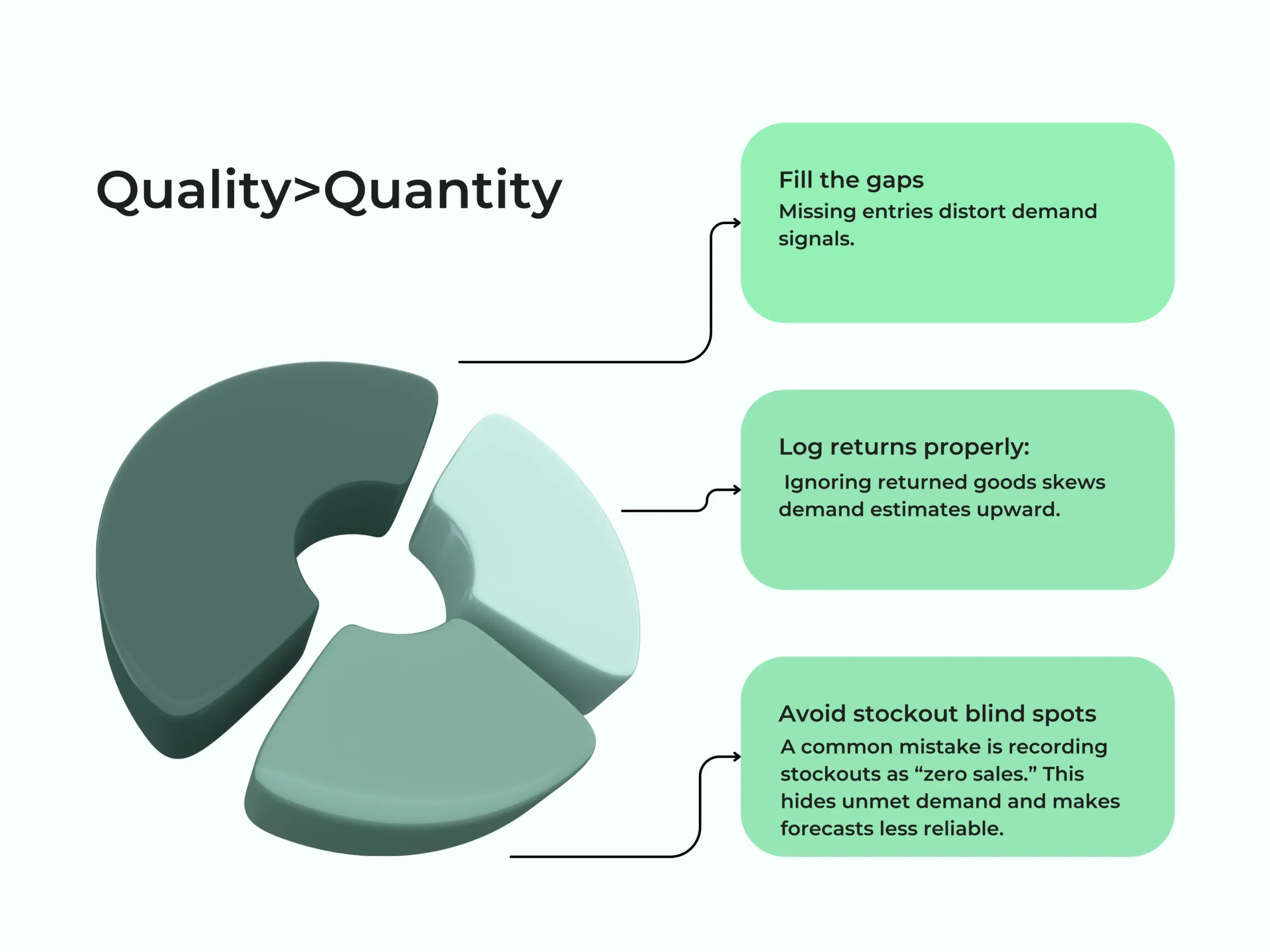

Every successful inventory forecast begins with data. Think of data as the raw ingredients of a recipe: if the ingredients are spoiled, the final dish will be ruined—no matter how skilled the chef is. The same is true with AI. Put simply: bad data = bad forecasts. AI doesn’t magically correct incomplete, messy, or inaccurate inputs—it amplifies them. That’s why the very first step in AI-powered forecasting is making sure the data you feed it is both reliable and relevant.

What Data Matters Most?

AI thrives on detail, but not every piece of information is equally valuable. Businesses should prioritize these four core data sources:

Sales History

Past sales tell the clearest story about customer demand. Patterns hidden in transaction history reveal seasonal highs, low-demand slumps, and recurring spikes. For example, a retailer might notice footwear sales peaking during back-to-school months, while an electronics company may see surges around major holidays. These signals give AI the baseline context to predict when demand will rise or fall.

Lead Times

How long does it take for suppliers to deliver after an order is placed? This seemingly small detail can make or break inventory planning. Even a two-day delay from a supplier can cause downstream stockouts if demand surges unexpectedly. Recording average lead times—and variations across different suppliers—helps AI align forecasts with realistic replenishment timelines.

Seasonal Trends

Beyond raw sales numbers, external factors drive fluctuations. Holiday surges, cultural events, regional preferences, or industry-specific buying cycles all shape demand. Think Valentine’s Day for florists or monsoon season for umbrella manufacturers. AI needs this context to avoid misinterpreting demand spikes as anomalies.

Supplier Performance

Not all suppliers are equal. Some consistently deliver on time and in full, while others may be prone to delays, shortages, or quality issues. Tracking performance history adds another layer of insight, enabling AI to weigh supply-side reliability when recommending reorder points. ts instead of reactive reports.

Step 2 – Train AI to Recognize Your Patterns

With the right data foundation in place, the next step is ensuring AI understands the rhythm of your business. Every company’s demand story is unique—what sells fast in one market may collect dust in another, and the timing of demand surges varies across industries. This is where training AI makes all the difference. Unlike traditional forecasting methods, which rely on rigid formulas, AI models are dynamic. They learn, adapt, and continuously improve as more information becomes available.

At its core, training AI is about teaching it to recognize and interpret your business signals.

- Historical data as the backbone

AI first analyzes your past sales records, promotions, stockouts, and order patterns to identify recurring cycles. Maybe demand always spikes the week before a major holiday or dips after the end of a fiscal quarter—these nuances get built into the model.

- Adding external context

Your business doesn’t operate in a vacuum. External factors such as inflation, competitor pricing strategies, new product launches, or even unexpected weather events can drastically shift demand. Modern AI forecasting systems can ingest these external signals alongside your internal data, creating more resilient predictions that hold up even in volatile markets.

- Ongoing learning and recalibration

Traditional models often generate a static forecast for a set period and stop there. AI is different—it keeps learning. Every new sales order, every delayed shipment, every promotion becomes another data point to refine the model. If something changes in real time—like a sudden surge from a viral TikTok trend—AI rapidly adapts and recalibrates its predictions to reflect the shift.

Step 3 – Monitor and Adjust in Real Time

Static forecasts are like snapshots—they capture a moment but quickly lose relevance. By the time a quarterly report lands on your desk, market conditions, customer behaviors, or supplier situations may have already shifted. That’s why businesses relying on fixed schedules often find themselves reacting too late rather than anticipating change.

AI-driven forecasting transforms this static approach into something dynamic: a constantly evolving forecast that updates itself with every transaction, shipment, or operational event. Think of it less as a forecast and more as a living system that learns and reacts in real time.

Here’s how it plays out in practice:

Live visibility at your fingertips

Instead of waiting for end-of-month or quarterly reports, AI forecasting brings inventory visibility in real time through interactive dashboards. These dashboards continuously track what products are moving quickly, which items are slowing down, and where risks might be building up in the supply chain. This means managers don’t just see a static report—they see a live story of their inventory as it unfolds. With this level of visibility, decision-making becomes proactive rather than reactive, helping businesses respond to shifts in demand or supply before they become costly problems.

Immediate response to disruptions

Disruptions such as supplier delays, transportation breakdowns, or sudden shifts in demand can throw off traditional forecasts. With AI, these disruptions are detected instantly, and their ripple effects on stock levels and customer commitments are clearly highlighted. This foresight gives businesses the ability to take corrective actions quickly rerouting stock, revising purchase orders, or proactively notifying customers about possible delays. Instead of scrambling after the fact, businesses can minimize the impact of disruptions before they escalate into major setbacks.

Smart buffer management

One of the biggest challenges in inventory management is balancing between overstocking and understocking. Traditional methods often rely on fixed safety stock levels, which may leave businesses either tying up too much capital in unused inventory or running short during demand spikes. AI-driven forecasting changes this by continuously adjusting safety stock based on live market signals and historical patterns. This dynamic buffer management ensures that businesses are neither overexposed to carrying costs nor unprepared for sudden surges in demand. The result is leaner, smarter inventory management that protects service levels while keeping costs in check.

Step 4 – Align Suppliers and Operations with AI Insights

Even the smartest forecast can fall flat if it lives in a silo. Forecasting in isolation might help you anticipate demand internally, but the real value comes when suppliers, procurement teams, sales, and operations are aligned around the same AI-driven insights.

Think of AI forecasting as the “single source of truth” that keeps the entire supply chain in sync. When everyone—from your suppliers to your sales reps—has visibility into the same dynamic forecast, decision-making becomes proactive rather than reactive. Here’s how the alignment creates impact across the business:

- Suppliers gain foresight. With access to AI-generated demand signals, they can plan production schedules, allocate raw materials, and avoid last-minute scramble to meet orders.

- Procurement teams negotiate smarter. With better predictability, they can secure long-term contracts, lock in favorable pricing, and reduce costly emergency purchases.

- Sales teams deliver with confidence. Knowing inventory levels are aligned with demand, they can set realistic customer expectations without the risk of overpromising.

- Operations teams stay fluid. Bottlenecks caused by mismatched supply and demand are minimized, keeping warehouse and distribution channels running smoothly.

- Finance teams stay ahead. With more accurate visibility into working capital and cash flow impacts, they can better plan budgets and investments.

Step 5 – Scale Across Locations and Product Lines

Growth is exciting—but it comes with layers of complexity. Managing inventory for one store is a challenge in itself. Now imagine adding multiple warehouses, hundreds (or even thousands) of SKUs, and shipping routes that span countries or continents. The margin for error multiplies, and manual planning simply can’t keep up.

This is where AI flexes its true strength. Unlike traditional systems that struggle with scaling, AI thrives on complexity. It doesn’t just crunch aggregate numbers; it delivers precision at both the big-picture and granular levels. Whether you’re overseeing a nationwide retail chain, a global distributor, or a fast-scaling eCommerce brand, AI ensures your forecasts remain accurate and actionable.

AI’s Role in Seamless Scaling

Centralized forecasting with local adaptability

AI creates a single, unified view of inventory forecasting across all your locations. But instead of applying a one-size-fits-all approach, it adjusts for local nuances like regional demand patterns, cultural preferences, and seasonal variations. This gives headquarters a centralized perspective while allowing local managers to plan effectively for their unique markets.

SKU-level accuracy

Instead of broad assumptions such as “winter jackets will sell well,” AI dives deeper to forecast demand at the SKU level—specific sizes, colors, or product variations. This eliminates costly overstocking of low-demand items and prevents stockouts of high-demand ones, ensuring better balance across your inventory.

Effortless scalability

When entering new markets or adding new product lines, AI seamlessly scales without requiring manual recalibration. It learns continuously from incoming data and adapts in real time. This means businesses can grow without being slowed down by the burden of redoing forecasts from scratch.

Supply chain synchronization

AI ensures demand forecasts align with supply chain operations across warehouses, suppliers, and logistics providers. By keeping every stakeholder aligned on the same plan, it minimizes delays, reduces waste, and strengthens overall supply chain efficiency, especially in complex multi-location environments.

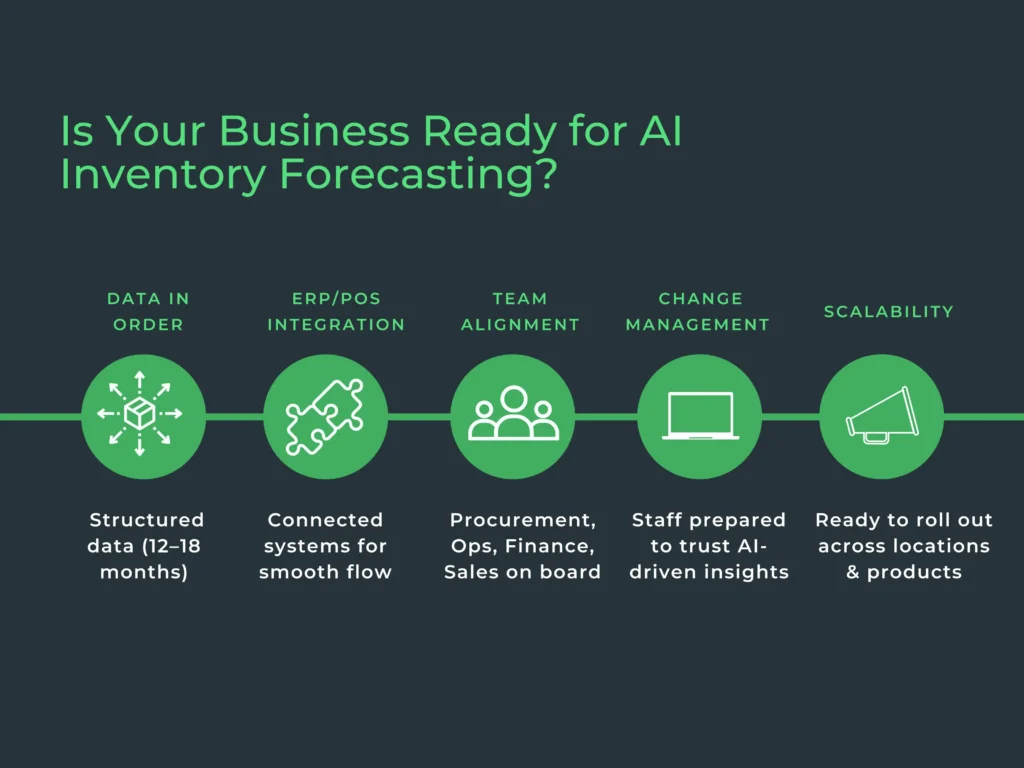

Quick Checklist: Is Your Business Ready for AI Inventory Forecasting?

Jumping into AI inventory forecasting without preparation can backfire. To make the most of the technology, your business needs a strong foundation. Use this checklist as a quick self-assessment before you take the leap:

1. Is your data in order?

AI is only as good as the data it’s trained on. If your sales, inventory, and supply chain records are incomplete, messy, or inconsistent across systems, forecasts will suffer. Ideally, you should have at least 12–18 months of clean, structured data to uncover meaningful seasonal patterns and trends.

2. Do you have ERP or POS integration ready?

AI forecasting thrives on real-time information. If your ERP, POS, or warehouse management system isn’t integrated, data silos will block the flow of insights. Ask yourself: can your current systems feed sales, returns, stock movements, and supplier data into a centralized platform? If yes, you’re ahead of the game.

3. Is your decision-making team aligned?

Technology won’t drive results if people don’t trust or adopt it. For AI forecasting to work, your procurement, operations, finance, and sales teams need to buy into the process. This means agreeing to use AI-generated insights in their planning, rather than relying on disconnected spreadsheets or intuition.

4. Do you have a plan for change management?

AI doesn’t just improve forecasts—it changes workflows. Planners will spend less time crunching numbers and more time making strategic calls. Leaders must prepare teams for this cultural shift and encourage collaboration across departments.

5. Are you ready to start small and scale?

Businesses often assume AI requires an all-or-nothing transformation. The truth? You can start small—perhaps with one product category or location—prove the value, and then scale across regions and product lines. AI platforms are designed to grow with you.

If you answered “yes” to most of these questions, your business is well-positioned to harness AI forecasting and see measurable impact.

If not, don’t worry—address the gaps step by step. Clean up data, integrate systems, and align your teams. Each improvement brings you closer to AI-driven efficiency.

Master Inventory Forecasting with AI – Explore More!

ConverSight.ai – AI Inventory Forecasting in Action

Talking about AI in theory is one thing, but seeing it in action is where the value truly comes alive. That’s exactly what ConverSight.ai brings to the table—taking the complexity of advanced forecasting models and making them not only powerful but also practical for everyday business users.

At the heart of ConverSight is Athena, the conversational AI assistant. Instead of navigating complicated dashboards or building custom reports, managers and planners can simply type or speak a question like, “What’s the forecasted demand for Product X next quarter?” or “Do we have enough inventory to cover the holiday season?” Within seconds, Athena delivers accurate, real-time insights in plain language. This means decision-makers don’t need a background in data science to access advanced forecasting—they just need to ask.

What makes ConverSight.ai stand out is its blend of intelligence and accessibility:

- Conversational AI at the Core – Natural language queries replace complex analytics tools, giving leaders instant access to predictions, alerts, and recommendations.

- Real-Time Analytics – Instead of relying on reports that are outdated the moment they’re exported, businesses get live insights that reflect actual conditions across warehouses, stores, and supply chains.

- Seamless Integrations – ConverSight plugs directly into ERP, CRM, and POS systems, ensuring data flows smoothly and forecasts are built on the most complete, up-to-date information available.

- Scalable Forecasting – Whether you’re tracking a handful of SKUs or thousands across multiple locations, the system adapts without missing a beat.

Real Results with AI Inventory Forecasting

Asia’s largest spice company transformed its forecasting and inventory management with ConverSight’s Athena AI. By shifting from manual forecasting to AI-driven models, the company improved demand accuracy, optimized inventory levels, and reduced waste from expired products. Athena’s ability to account for seasonality, pricing, and purchasing behaviors enabled real-time adjustments, streamlined procurement, and empowered sales teams with predictive insights—leading to stronger performance and greater confidence in supply chain planning.

Key Results

- 30% improvement in forecasting accuracy.

- 20% reduction in inventory waste.

- 50% fewer computational resources.

See How ConverSight Transforms AI Inventory Forecasting Accuracy → Read the Case Study

Conclusion

AI inventory forecasting isn’t just a tech upgrade—it’s a strategic edge in today’s unpredictable market. Traditional methods leave businesses vulnerable to shortages, overstocks, and missed opportunities. But by following the five steps outlined here—collecting the right data, training AI models, monitoring performance in real time, aligning with suppliers, and scaling across locations—organizations can transform inventory management from a reactive scramble into a proactive, precision-driven process.

The payoff goes beyond operational efficiency. With AI-powered forecasting, companies build resilience against market volatility, strengthen supplier relationships, and deliver consistently better customer experiences. In a landscape where speed, accuracy, and adaptability define success, AI equips businesses to anticipate demand instead of merely responding to it.

The future of inventory management is already here. The choice is clear: embrace AI to lead with confidence—or risk falling behind those who already have. With ConverSight, you can take the first step today – Click Here to Explore!