Improving Decision-Making, Operational Flow, and Adaptability with Decision Intelligence Supply Chain

What Is Decision Intelligence?

Global supply chains are more dynamic, interconnected, and fragile than ever before. Businesses must contend with rising customer expectations, geopolitical shifts, climate disruptions, fluctuating costs, and increasing pressure for sustainability. Traditional management tools — spreadsheets, siloed dashboards, and gut instinct — are no longer enough to keep pace with the complexity of modern operations.

To compete and thrive, organizations need smarter, faster, and more adaptive ways to make decisions. That’s where the Decision Intelligence Supply Chain model comes in. By unifying artificial intelligence (AI), advanced analytics, automation, and human expertise, decision intelligence (DI) transforms how supply chains anticipate disruptions, optimize operations, and seize opportunities.

This blog explores what decision intelligence is, how it differs from traditional BI, why it matters now, and the keyways a Decision Intelligence Supply Chain helps companies become more resilient, efficient, and future-ready.

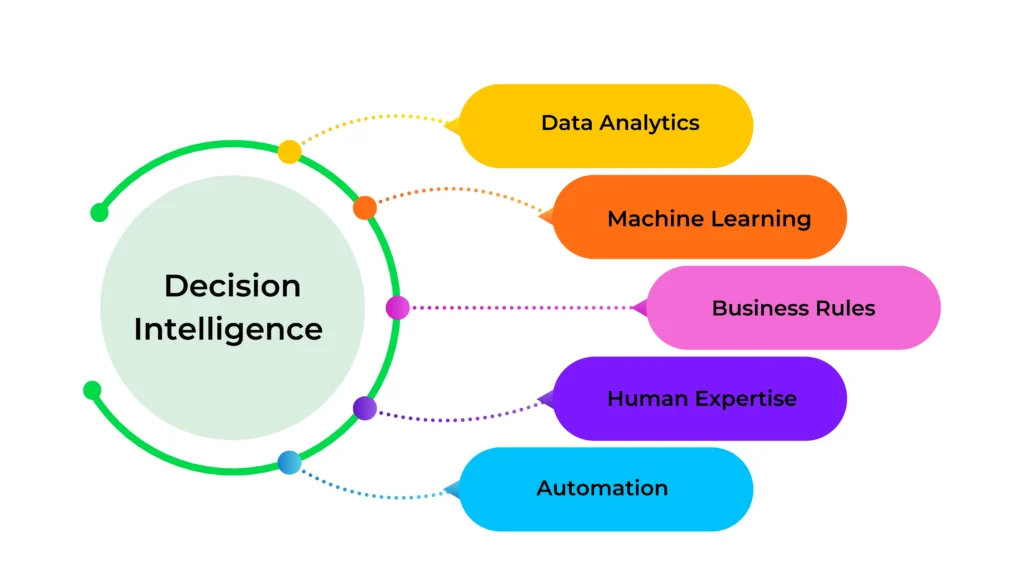

Definition:

Decision intelligence (DI) is a discipline that uses data science, AI, machine learning, business logic, and automation to support and improve human decision-making. Unlike business intelligence (BI), which stops at reporting on what happened, DI goes further by simulating scenarios, predicting outcomes, recommending optimal actions, and — in many cases — executing those actions automatically.

At its core, DI seeks to answer four critical questions:

- What is happening right now? (descriptive)

- Why is it happening? (diagnostic)

- What is likely to happen next? (predictive)

- What should we do about it? (prescriptive and actionable)

When applied to global operations, a Decision Intelligence Supply Chain solution enables leaders to:

- Detect risks in real time

- Simulate “what-if” scenarios before disruptions occur

- Balance trade-offs between cost, speed, and service

- Automate repetitive operational decisions

Supply Chain Decision Intelligence vs. Traditional Inventory Tools

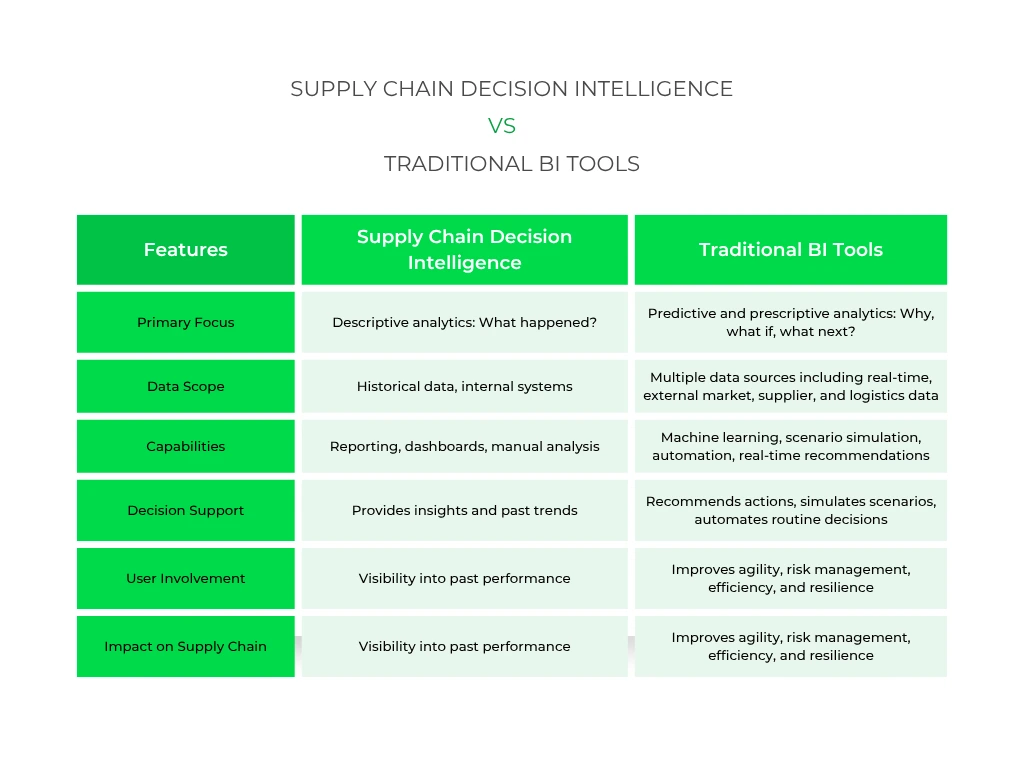

Traditional inventory and planning tools rely heavily on historical data, manual inputs, and static reporting. While they provide visibility into past performance, they often lack real-time adaptability, predictive insights, and the ability to coordinate actions across the supply chain.

Key Differences:

- Data Handling: Traditional tools report on what happened; Decision Intelligence anticipates trends, simulates scenarios, and recommends actions.

- Automation: Traditional tools require manual updates and interventions; Decision Intelligence can autonomously execute decisions, such as reordering stock or rerouting shipments.

- Adaptability: Traditional systems are static and inflexible; Decision Intelligence adapts to market shifts, disruptions, and changing customer demand in real time.

- Collaboration: Decision Intelligence enables multi-agent collaboration across procurement, production, logistics, and sales—something traditional tools cannot orchestrate effectively.

Supply Chain Decision Intelligence vs. Traditional BI Tools

While both Decision Intelligence (DI) and traditional Business Intelligence (BI) tools aim to help companies understand their data, they differ significantly in scope, capability, and impact—especially when applied to complex supply chains.

Why Decision Intelligence Supply Chain Strategies Are Critical Today

In today’s interconnected global economy, supply chains face unprecedented challenges. A survey found that 93% of supply chain leaders are planning to increase resilience in their networks, highlighting the urgency to adapt to disruptions and uncertainties.

Decision Intelligence (DI) integrates real-time data, machine learning, predictive models, and automation to transform decision-making. Instead of reacting after problems occur, supply chain teams using DI can anticipate disruptions, optimize inventory, adjust logistics on the fly, and improve supplier collaboration—all while saving time and reducing human error.

Implementing DI in supply chain operations leads to significant benefits:

- Enhanced Efficiency: By automating routine decisions and optimizing processes, companies can reduce operational costs and improve service levels.

- Increased Resilience: DI enables organizations to anticipate and mitigate risks, ensuring continuity in the face of disruptions.

- Competitive Advantage: Companies leveraging DI can respond faster to market changes, aligning supply chain strategies with business objectives more effectively.

For example, Gartner reports that by 2028, 25% of KPI reporting will be powered by GenAI models, indicating a significant shift towards AI-driven decision-making in supply chains.

Key Areas Where Decision Intelligence Supply Chain Platforms Deliver Value

Demand Forecasting with Greater Precision

One of the most immediate areas where DI delivers results is demand forecasting. Instead of relying only on past sales or seasonal patterns, DI draws on historical sales, real-time market signals, external data like weather or economic shifts, and even social sentiment to predict future demand with far greater precision. This improved forecasting allows companies to plan production, purchasing, and distribution more accurately, reducing stockouts, avoiding excess inventory, and ensuring smoother operational flow.

Smarter Inventory Optimization

Inventory management is another area being transformed by DI. By continuously analyzing inventory levels, supplier lead times, customer demand changes, and the costs of storage or transportation, DI identifies the optimal stock levels for each location. This means businesses can reduce excess inventory, cut carrying costs, improve working capital, and still meet customer service expectations. The result is a leaner, more agile supply chain that responds efficiently to market shifts.

Stronger Supply Chain Risk Mitigation

Supply chain disruptions — whether caused by geopolitical events, raw material shortages, or logistical delays — can devastate operations. DI strengthens risk mitigation by monitoring global data, supplier health metrics, and logistics signals to detect early warning signs of trouble. With these insights, businesses can take preemptive action, such as shifting suppliers, adjusting procurement plans, or revising delivery schedules. This proactive approach helps companies stay resilient and recover faster when unexpected events occur.

Optimizing Logistics and Transportation

Logistics and transportation, often the most complex and cost-heavy parts of the supply chain, benefit significantly from DI. By analyzing real-time data like traffic conditions, weather, fuel prices, capacity constraints, and carrier performance, DI enables dynamic routing, shipment consolidation, and optimal carrier selection. This leads to faster deliveries, lower transportation costs, improved on-time performance, and happier customers — all while adapting to constantly changing external conditions.

Building Blocks of a Decision Intelligence Supply Chain

To unlock the full potential of a Decision Intelligence Supply Chain, companies need five essential enablers that work together to connect data, intelligence, and action.

Data Integration Layer

Decision intelligence starts with data. By connecting ERP, CRM, IoT sensors, supplier feeds, and external signals such as weather or market data, businesses create a single, trusted source of truth. This eliminates silos and ensures decisions are based on real-time, accurate insights.

AI & Machine Learning Models

AI and ML serve as the analytical engine. Forecasting, optimization, anomaly detection, and simulation models help predict demand, detect risks, and test “what-if” scenarios. For example, retailers can simulate multiple demand outcomes during peak season and prepare accordingly.

Decision Frameworks

Business rules and policies guide AI recommendations, ensuring they align with corporate priorities. A Decision Intelligence Supply Chain might prioritize sustainable suppliers, protect margins during shortages, or balance speed against cost. These frameworks keep automation consistent with strategy.

Automation Tools

Automation allows approved decisions to be executed instantly, without delays. This may include rerouting shipments in real time, triggering purchase orders when thresholds are met, or adjusting production schedules dynamically. The result: a more agile and responsive network.

User Interfaces

Insights must be accessible to be useful. Dashboards and conversational AI assistants make intelligence available to planners, executives, and frontline staff. A supply chain manager can simply ask, “How will supplier delays in Asia affect Q4 margins?” and receive immediate, actionable insights.

Implementing Decision Intelligence Supply Chain Solutions

Transitioning to a DI-driven supply chain is a journey, not a one-time project. It requires clear priorities, phased execution, and organizational buy-in.

Step-by-Step Roadmap

- Assess Current State: Map out existing processes, data silos, and bottlenecks. Identify where manual decision-making slows down operations or creates risk.

- Prioritize High-Impact Use Cases: Begin with areas that deliver visible ROI — demand forecasting, logistics optimization, or inventory planning. Quick wins build trust and momentum.

- Integrate Data Sources: Connect ERP, CRM, IoT, supplier, and external data feeds. Ensure data governance policies are in place for accuracy and consistency.

- Leverage AI & Automation Gradually: Start with decision support (recommendations) before progressing to partial or full automation. This staged approach reduces resistance.

- Change Management & Training: Provide workshops and simulations to help planners understand and trust DI recommendations. Build a culture of human–AI collaboration.

- Iterate and Expand: Scale to other areas once early use cases prove successful. Over time, build a fully integrated Decision Intelligence Supply Chain spanning procurement, production, logistics, and customer service.

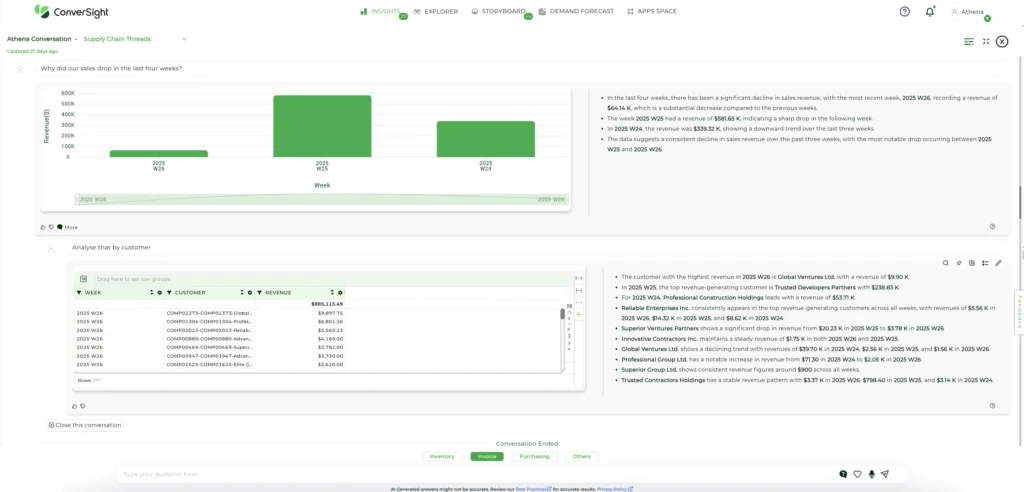

ConverSight: Powering the Decision Intelligence Supply Chain

While the concept of a Decision Intelligence Supply Chain is powerful, organizations need a practical platform to bring it to life. That’s where ConverSight comes in. ConverSight is a unified decision intelligence platform designed to deliver real-time insights, predictive analytics, and automated recommendations across the entire supply chain ecosystem.

BI + Supply Chain + AI = ConverSight

How ConverSight Enables Decision Intelligence

ConverSight with 150+ data connectors can integrate seamlessly with ERP, CRM, and supply chain systems to unify data streams, apply AI models, and surface actionable recommendations. With natural language interfaces, users don’t need to be data scientists to access intelligence — they can simply ask questions and receive instant answers.

Key capabilities include:

- Conversational AI Assistant – Supply chain planners can ask questions like, “What’s our optimal safety stock for next quarter?” and receive actionable insights in seconds.

- Predictive Analytics – Forecasts demand, inventory needs, and logistics risks before they happen.

- Automated Workflows – Executes repetitive actions such as reordering, rerouting, or adjusting schedules.

- Scenario Simulation – Models “what-if” scenarios to prepare for disruptions like supplier delays or demand spikes.

Benefits for Users

Adopting ConverSight for a Decision Intelligence Supply Chain delivers tangible benefits to different stakeholders:

- Executives gain a real-time view of supply chain health and risk exposure.

- Planners save hours previously spent on manual analysis and can focus on strategic decision-making.

- Procurement teams can negotiate with suppliers more effectively by accessing predictive cost and lead-time insights.

- Logistics managers can dynamically adjust routing and carrier selection to cut costs and improve delivery reliability.

- Finance teams gain foresight into cost fluctuations and margin impacts tied to supply chain events.

Why ConverSight Stands Out

Unlike traditional BI dashboards or niche AI tools, ConverSight combines conversational AI, predictive analytics, and automated execution into a single platform. This makes it easier for teams to act quickly and collaboratively, enabling organizations to transition from reactive firefighting to proactive, intelligence-driven supply chain management.

Conclusion

In today’s fast-moving, unpredictable world, supply chains need more than just data — they need intelligence. Decision Intelligence is transforming how businesses manage their supply chains by delivering predictive insights, real-time adaptability, and smarter, faster decision-making.

ConverSight delivers a unified Decision Intelligence Supply Chain enabling leaders to anticipate disruptions and act with confidence. ConverSight empowers supply chain leaders to navigate sudden changes, disruptions, and market demands with confidence. By combining AI-driven analytics, automated insights, and intuitive decision tools, ConverSight helps businesses stay resilient, agile, and ahead of the competition — no matter what challenges arise.

Ready to Transform Your Supply Chain?

Download the Whitepaper to see how Decision Intelligence helps you tackle tariff challenges and strengthen your supply chain.