Enhancing Efficiency, Quality, and Decision-Making in Food Manufacturing with AI

Why Food Manufacturing Needs AI Today

The food and beverage industry is evolving rapidly. Rising consumer expectations, stricter regulations, and frequent supply chain disruptions are forcing manufacturers to operate more efficiently, make smarter decisions, and stay ahead of demand.

Artificial intelligence (AI) is no longer just automation—it creates intelligent systems that predict, optimize, and adapt in real time. By integrating AI into manufacturing, companies can eliminate inefficiencies, enhance product quality, and boost profitability. For manufacturers handling perishable goods, unpredictable demand, and strict compliance requirements, AI is essential for real-time production optimization and predictive quality control.

Top Challenges in Modern Food Manufacturing

Modern food manufacturing operates in an environment that demands speed, precision, and adaptability. While the industry has made major strides in automation and equipment, many operations still rely on outdated reporting systems, siloed data, and manual processes that can’t keep up with real-time production demands. These gaps lead to lost efficiency, unnecessary waste, and reduced profitability.

Below are the key challenges holding many food manufacturers back — and why intelligent, AI-driven systems are becoming essential.

Manual Reporting and Slow Analytics

In many food production facilities, data collection still happens through spreadsheets, clipboards, or disconnected systems. Reporting is often reactive, meaning decisions are made based on what happened yesterday rather than what’s happening now. This time lag prevents teams from making proactive adjustments to production schedules, demand fluctuations, or quality issues.

Without AI-driven reporting, plant managers and supply chain teams struggle to answer simple questions in real time: How much product do we have left? Are we on track with production goals? Are any machines showing signs of failure? Slow insights mean slower responses, which can quickly cascade into costly operational delays.

Inventory Waste and Inefficiency

Food manufacturing faces a unique challenge: perishability. Unlike durable goods, ingredients and finished products often have short shelf lives. Overestimating demand leads to spoiled inventory, while underestimating it can create production gaps and stockouts.

Traditional forecasting methods rely on historical averages and manual calculations, which are often inaccurate. As a result, manufacturers end up either overproducing — increasing waste and costs — or underproducing, leading to lost revenue opportunities and unhappy customers.

Quality Inconsistencies

Consistency is everything in food production. A single batch of off-spec product can affect brand trust, regulatory compliance, and consumer safety. Manual quality checks are prone to human error and may not catch subtle defects or contamination in time.

Without automated, AI quality control, issues are often detected too late — after products have already left the production line. This can result in product recalls, compliance fines, or customer dissatisfaction.

Supply Chain Complexity

Globalized supply chains make food manufacturing increasingly complex. Ingredient sourcing, logistics, cold chain management, and distribution all need to work in harmony. Any disruption — from weather delays to labor shortages — can affect production timelines.

Traditional supply chain monitoring often lacks visibility and predictive capabilities. Manufacturers may not know about a potential disruption until it’s too late to act. This lack of agility impacts efficiency, customer service, and cost control.

AI Use Cases in Manufacturing

Artificial Intelligence is no longer a “future technology”—it is actively transforming manufacturing processes across multiple industries, from automotive to electronics, pharmaceuticals, and food production. By going beyond historical data and reactive decision-making, AI provides real-time insights, predictive intelligence, and automated workflows that help manufacturers operate smarter, faster, and more efficiently.

For food manufacturers, AI’s value is especially pronounced. It helps manage perishable goods, maintain quality standards, optimize inventory, and adapt quickly to market fluctuations. Below, we explore the most impactful AI use cases in modern manufacturing, with practical applications for food and beverage operations.

Predictive Maintenance

Unplanned downtime is a major cost driver in food manufacturing, as a single machine failure can halt production, delay shipments, and increase expenses. AI continuously monitors equipment using sensor data and machine learning to detect early signs of wear or malfunction. By predicting failures, maintenance teams can schedule repairs proactively, reduce unexpected disruptions, extend equipment lifespan, and optimize resource allocation. For instance, a beverage bottling plant can detect abnormal vibrations or temperature fluctuations and act before costly downtime occurs.

Key benefits for food manufacturers:

- Minimized downtime and production delays

- Extended equipment life

- Reduced maintenance costs and emergency repairs

- Increased operational efficiency and throughput

Process Automation

Many manufacturing tasks, such as data entry, packaging, labeling, and equipment calibration, are repetitive and low-value. AI-driven process automation replaces manual operations with intelligent systems that execute tasks accurately and efficiently. In food production, automation can adjust mixing times based on ingredient data, update inventory logs automatically, or control packaging machinery. By relieving employees from repetitive work, AI allows them to focus on strategic activities like quality improvement, recipe innovation, and customer experience.

Key benefits for food manufacturers:

- Increased operational efficiency

- Reduced human error and inconsistency

- Streamlined workflows and faster turnaround times

- Empowered workforce focusing on higher-value tasks

Demand Forecasting

Traditional forecasting often relies on historical averages and fails to capture sudden market shifts, seasonal trends, or external factors. AI analyzes multiple data sources—including sales history, POS data, supply chain trends, and market indicators—to generate highly accurate predictions. For example, a dairy manufacturer can anticipate seasonal demand for flavored milk and adjust production schedules proactively, preventing overproduction or shortages.

Key benefits for food manufacturers:

- Accurate demand predictions for perishable and seasonal products

- Reduced food waste and inventory overstock

- Optimized production schedules and resource utilization

- Enhanced customer satisfaction through better availability

Inventory Optimization

Managing inventory in food manufacturing is challenging due to perishability. AI analyzes historical consumption, demand fluctuations, and lead times to recommend optimal stock levels for raw materials and finished goods. For instance, a bakery can forecast daily bread demand at each outlet to avoid surplus while ensuring availability.

Key benefits for food manufacturers:

- Reduced spoilage and food waste

- Lower inventory carrying costs

- Balanced stock levels and timely replenishment

- Improved cash flow and operational efficiency

Supply Chain Visibility

Food supply chains are complex, involving multiple suppliers, distributors, and logistics partners, where disruptions can cascade across production. AI provides end-to-end visibility, identifies potential disruptions, predicts shipping delays, and optimizes routing to ensure timely deliveries and maintain product quality. In temperature-sensitive supply chains, AI monitors cold chain conditions and proactively addresses issues.

Key benefits for food manufacturers:

- Predictive insights into supply chain disruptions

- Optimized logistics and delivery schedules

- Improved coordination between procurement, production, and distribution

- Enhanced customer satisfaction through reliable supply

How AI Use Cases Apply to Food Manufacturing

The food and beverage industry faces challenges unlike any other sector—perishable ingredients, strict safety regulations, unpredictable demand, and complex supply chains all put immense pressure on manufacturers. While AI has proven transformative across manufacturing in general, its potential in food production is particularly significant.

By embedding intelligence into every stage—from forecasting demand and scheduling production to monitoring quality and optimizing supply chains—AI enables food manufacturers to operate with greater precision, agility, and reliability. These technologies don’t just automate tasks—they provide actionable insights, anticipate problems before they occur, and allow teams to respond in real time, helping organizations deliver consistent quality, reduce waste, and meet consumer expectations more effectively.

Forecasting Demand Spikes in Perishable Goods

Accurately predicting demand is critical in food production, where perishable goods have a limited shelf life. Traditional forecasting methods often rely on historical averages, which fail to capture sudden spikes caused by seasonal changes, market trends, or external factors like weather events or promotions.

AI-driven demand forecasting uses machine learning algorithms to analyze multiple data sources — including historical sales, supply chain patterns, point-of-sale data, and external signals. This enables manufacturers to anticipate demand shifts early, adjust production schedules accordingly, and avoid both overproduction and underproduction.

For example, a sudden increase in demand for a particular beverage during summer can be detected weeks in advance. AI allows the manufacturer to ramp up production efficiently — meeting consumer demand without excess inventory or waste.

Reducing Food Waste Through Real-Time Production Adjustments

One of the biggest pain points in food manufacturing is waste. Perishable ingredients can expire quickly, and even small mismatches between production and demand can lead to significant losses.

With AI real-time monitoring and production optimization, manufacturers can adjust batch sizes, ingredient usage, and processing timelines dynamically. AI systems continuously analyze live data from production lines, supply chains, and sales channels to recommend immediate actions — like slowing down production during a demand dip or accelerating output during a surge.

Ensuring Quality and Safety Compliance Using AI Sensors and Cameras

Food quality and safety aren’t negotiable. Contamination, foreign objects, or irregularities can lead to regulatory penalties, product recalls, and brand damage. Traditional manual inspections are often inconsistent and time-consuming.

AI vision systems combined with advanced sensors provide real-time quality monitoring throughout the production line. These systems can detect even minute deviations in product size, shape, color, or composition. When an issue arises, the system triggers instant alerts, allowing operators to address the problem before it impacts a larger batch.

Automating Batch Production Scheduling for Efficiency

Food manufacturing often involves complex batch production cycles where timing, ingredient ratios, and sequencing must be precise. Manual scheduling can lead to bottlenecks, delays, or uneven resource utilization.

AI automates this process by analyzing production data, resource availability, and demand forecasts to create optimal production schedules. This ensures that the right products are produced at the right time — with minimal downtime and maximum throughput.

By automating scheduling, manufacturers can reduce operational inefficiencies, improve delivery timelines, and enhance capacity planning.

Benefits of AI in Food Manufacturing

The integration of AI into food manufacturing goes far beyond simple automation—it fundamentally enhances how businesses operate, make decisions, and respond to challenges. By leveraging advanced analytics, machine learning, and real-time monitoring, AI empowers manufacturers to work smarter, reduce risks, and achieve operational excellence. The benefits span multiple dimensions, from efficiency and sustainability to quality assurance and profitability.

- Efficiency & Speed:

AI automates data collection, reporting, and process control, allowing manufacturers to make faster, more informed decisions. Real-time analytics enable quick responses to demand fluctuations, reducing downtime and increasing production output.

- Sustainability:

By optimizing ingredient usage and production runs, AI minimizes excess inventory and reduces food waste. It also helps manufacturers manage energy consumption efficiently, supporting eco-friendly operations and regulatory sustainability goals.

- Quality & Compliance:

AI-driven monitoring systems ensure every batch meets strict quality and safety standards. With the help of sensors and computer vision, any deviations in temperature, texture, or hygiene can be instantly flagged, ensuring consistent product quality and regulatory compliance.

- Profitability:

Smarter forecasting, precise scheduling, and reduced inefficiencies translate into significant cost savings. AI enables manufacturers to align production more closely with actual demand, optimize labor and material use, and ultimately boost profit margins.

AI Success Stories in Food Manufacturing

Food manufacturers operate in a highly dynamic environment, dealing with perishable products, fluctuating consumer demand, and complex supply chain challenges. Traditional forecasting methods, manual inventory management, and disconnected data systems often lead to inefficiencies such as overstocking, stockouts, and production delays. By adopting advanced AI-driven solutions, companies can gain predictive insights, optimize production planning, and reduce waste — turning these challenges into opportunities for operational excellence.

Hodo Foods

Hodo Foods faced several critical issues:

- Unpredictable demand: Seasonal trends, market fluctuations, and promotions made it difficult to anticipate exactly how much product to produce.

- Inaccurate inventory tracking: Manual methods and disconnected systems led to errors in knowing stock levels in real time.

- Complex supplier coordination: Multiple suppliers with varying lead times made planning and procurement challenging.

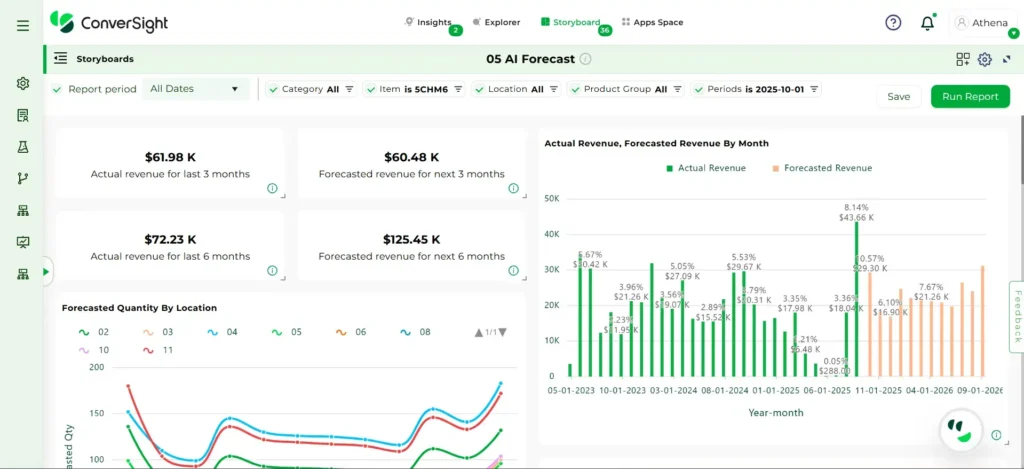

AI Solution with ConverSight:

ConverSight implemented its AI-powered Decision Intelligence platform to tackle these challenges:

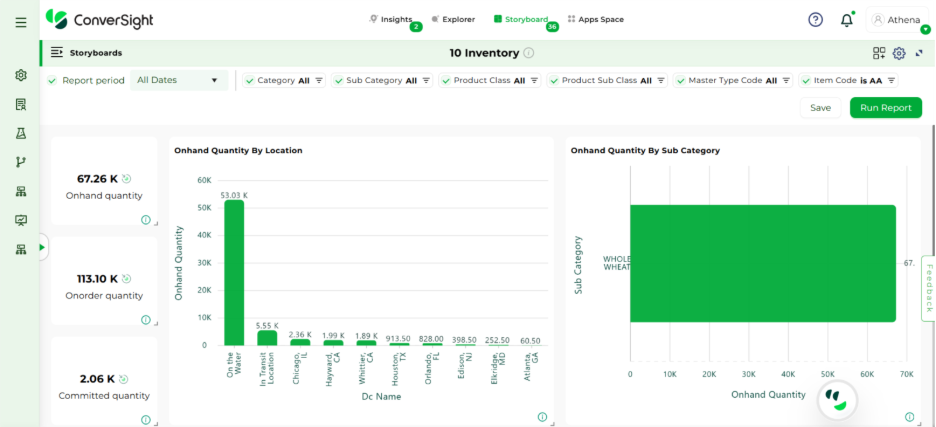

- Real-time visibility: By integrating AI with inventory and production data, Hodo Foods could monitor stock levels and production in real time.

- Dynamic demand forecasting: AI analyzed historical sales, market trends, and supply chain patterns to predict demand accurately, allowing the company to produce the right quantities at the right time.

- Smart purchase recommendations: AI suggested optimal quantities for procurement, reducing excess inventory.

- Automated work order scheduling: Production orders were optimized based on demand predictions, minimizing downtime and ensuring smooth operations.

Results:

- 35% fewer stockouts

- 28% reduction in inventory costs

- 70% faster reporting

House of Spice (HOS)

House of Spice manages thousands of SKUs, many of which are perishable. The company struggled with:

- Manual forecasting errors: Relying on spreadsheets and static methods often resulted in overstocking or stockouts.

- Complexity of inventory management: Thousands of SKUs and varying shelf lives made precise planning extremely difficult.

AI Solution with ConverSight:

- Athena AI assistant: Provided predictive insights in real time, allowing planners to make data-driven decisions quickly.

- Advanced forecasting models: Accounted for seasonality, price changes, market demand shifts, and purchasing patterns, ensuring more accurate forecasts.

- Real-time adjustments: Continuously monitored actual sales and stock levels, recommending immediate adjustments to production and procurement plans.

- Optimized inventory levels: Fine-tuned inventory quantities to match demand, minimizing waste and improving availability.

Results:

- 20% reduction in waste

- 30% improvement in forecasting accuracy

Read more about real-world success with ConverSight — Case Studies

Overcoming Barriers to AI Adoption

Adopting AI in food manufacturing can feel intimidating. Common concerns include high costs, integration complexity, and the need for specialized skills. Many organizations assume that implementing AI requires hiring data scientists, investing heavily in IT infrastructure, or completely overhauling existing systems.

ConverSight QuickStart AI eliminates these obstacles by offering plug-and-play AI decision intelligence tailored for supply chain, finance, and sales operations. Instead of spending hours building reports or reconciling disconnected data, food manufacturers can gain real-time visibility, AI forecasting, and intelligent automation directly from their ERP system. This allows teams to anticipate demand changes, optimize inventory, and make faster, data-driven decisions—all without complex IT setups or technical expertise.

Key ways ConverSight simplifies AI adoption include:

- Seamless Integration: ConverSight connects directly, enabling instant access to actionable insights from ERP data. There’s no need for lengthy implementations, ensuring teams can start benefiting from AI immediately.

- Athena AI Employee: The natural language AI assistant, Athena, allows employees to ask questions and receive insights in real time. Users can quickly analyze trends, generate reports, and forecast demand without relying on specialized analytics teams.

- Scalable AI Modules: Companies can adopt AI incrementally, starting with high-impact areas like demand forecasting, inventory optimization, or production planning. Once proven, these modules can be scaled across operations for maximum impact.

- Intelligent Forecasting and Planning: ConverSight moves beyond static reports by providing dynamic AI-driven forecasts and scenario planning. Teams can anticipate market shifts, balance supply with demand, and proactively adjust production schedules.

- Accelerated Supply Chain Visibility: Real-time insights into inventory, demand, and supplier performance enable faster, more informed decision-making. Manufacturers can identify potential disruptions early and take corrective action to maintain efficiency and service levels.

- Rapid ROI and Operational Efficiency: By automating repetitive tasks, reducing reporting cycles, and optimizing inventory, ConverSight drives measurable results. Food manufacturers see up to 30% improvement in forecasting accuracy, 75% reduction in manual reporting and planning time, and 20% reduction in inventory waste, improving overall profitability and operational resilience.

By addressing concerns around cost, complexity, and skills, ConverSight democratizes AI for food manufacturing. Teams no longer need to rely on static reports or siloed data—they can leverage intelligent insights to make faster, more confident decisions, reduce waste, improve compliance, and enhance overall operational efficiency. This approach ensures that even organizations with limited AI expertise can unlock the full potential of their ERP data and achieve a smarter, more responsive food supply chain.

CTA: Explore how ConverSight delivers AI-driven visibility and forecasting — Learn More

Implementing AI: Best Practices

Successfully adopting AI in food manufacturing requires more than technology—it demands a structured approach that aligns AI capabilities with business goals. By following best practices, manufacturers can maximize ROI, improve operational efficiency, and drive sustainable growth.

- Define Clear Objectives

Start by identifying the specific challenges you want AI to address, such as demand forecasting, inventory optimization, production scheduling, or quality control. Align these AI initiatives with overall business strategy to ensure they support measurable outcomes and operational goals.

- Ensure Data Quality and Integration

AI models are only as effective as the data they rely on. Centralize and clean data from ERP, CRM, and production systems, ensuring it is accurate, complete, and standardized. For companies using Microsoft Dynamics 365, ConverSight seamlessly integrates with ERP data to provide a unified view across sales, inventory, and supply chain processes. High-quality, connected data enables reliable AI forecasting, insights, and decision-making.

- Start Small and Scale Gradually

Pilot projects allow teams to test AI in high-impact areas before wider deployment. Begin with a single production line, inventory process, or demand forecast. Once the pilot demonstrates measurable improvements—such as reduced waste, faster reporting, or better forecast accuracy—expand AI across additional operations for a controlled and scalable rollout.

- Leverage AI for On-Demand Insights

Empower teams to access real-time data and generate actionable insights quickly. ConverSight’s Athena AI assistant allows employees to query data in natural language, producing forecasts, inventory reports, and performance metrics instantly. Automating routine reporting and analysis frees employees to focus on strategic decisions that drive efficiency and profitability.

- Monitor, Measure, and Iterate

Track key performance indicators such as production efficiency, waste reduction, forecasting accuracy, and supply chain responsiveness. Continuously refine AI models based on outcomes to improve predictive capabilities over time. Iterative learning ensures AI adapts to changing market conditions, seasonal demand, and operational variations.

- Train Teams and Encourage Collaboration

Education is critical for adoption. Train employees to understand AI outputs, interpret predictions, and act on insights. Promote cross-functional collaboration by ensuring sales, procurement, production, and quality teams can leverage shared AI data to make coordinated, data-driven decisions.

- Prioritize Security and Compliance

Protect sensitive production, sales, and supply chain data while ensuring AI solutions comply with food safety and regulatory standards. ConverSight’s platform maintains data integrity and security, enabling manufacturers to harness AI without compromising compliance or privacy.

Future Trends: The Next Generation AI in Food Manufacturing

The next generation of food manufacturing will be defined by autonomous factories, robotics integration, and AI-driven personalization. Real-time analytics will enable sustainable production, allowing manufacturers to optimize resources, reduce waste, and respond instantly to changing consumer demand.

AI is no longer optional—it’s essential for staying competitive, improving operational efficiency, and ensuring consistent quality in a rapidly evolving industry. By leveraging AI insights, food manufacturers can transform their operations, make smarter decisions, and achieve both growth and sustainability goals.

Transform your operations with AI-powered insights — Discover ConverSight